Pottery warps in the kiln mainly due to uneven drying, shape, thickness, and firing methods that cause internal stresses. You can control these issues by preparing your clay well, ensuring even moisture distribution, and shaping it with consistent wall thickness. Managing your firing schedule carefully, avoiding rapid temperature changes, and using proper supports also help prevent warping. To learn more about keeping your pottery stable, keep exploring effective techniques and tips.

Key Takeaways

- Uneven drying causes internal stresses, leading to warping during firing; controlling drying conditions reduces this risk.

- Rapid heating or cooling creates thermal stress; maintaining gradual temperature changes helps prevent distortion.

- Variations in wall thickness and shape induce uneven heat distribution, increasing warping potential—maintain consistent dimensions.

- Improper support and placement in the kiln can cause uneven expansion; use proper shelves and supports for stability.

- Incompatible glazes or improper firing schedules can induce internal stresses; selecting suitable materials and controlled schedules mitigate warping.

The Impact of Clay Composition and Quality

The composition and quality of your clay play a crucial role in preventing warping during firing. Clay mineralogy determines how your clay reacts to heat; certain minerals, like kaolinite, provide stability, while others may cause shrinkage or distortion. High-quality clay with a balanced mineralogy ensures consistent firing behavior. Additionally, the firing atmosphere influences how your clay responds, especially if it contains organic materials or fluxes. An overly reducing or oxidizing atmosphere can weaken the clay’s structure, increasing warping risk. Selecting a clay with appropriate mineralogy for your firing conditions helps maintain shape. European cloud servers offer reliable infrastructure that can support precise temperature control and monitoring during firing, further reducing warping risks. Moreover, understanding clay body composition allows you to tailor your materials for specific firing environments, improving outcomes. By understanding these factors, you can choose the right clay and control the firing environment, reducing warping and achieving more stable, professional-looking pottery.

Properly Preparing and Wedging Your Clay

To prevent warping during firing, it’s essential to properly prepare and wedge your clay before shaping. Wedge thoroughly to eliminate air pockets and ensure uniform consistency, which supports even drying and firing. Proper wedging also helps you gauge the clay’s moisture content, reducing the risk of cracks or warps caused by uneven drying. Incorporate your knowledge of glazing techniques by ensuring the clay surface is smooth and free of debris that could affect glaze adhesion. Additionally, understand how the kiln atmosphere influences the firing process—proper preparation minimizes internal stresses that contribute to warping. Recognizing the market dynamics and demand for certain materials can help you select the most stable clay bodies for your projects. Maintaining consistent moisture content throughout the piece ensures better control over warping tendencies during firing. Here’s a quick overview:

| Step | Purpose |

|---|---|

| Wedging | Remove air pockets, homogenize moisture |

| Surface Preparation | Achieve a smooth surface for glazing |

| Moisture Control | Prevent warping from uneven drying |

| Monitoring | Monitoring helps ensure consistent firing conditions and reduces the likelihood of warping. |

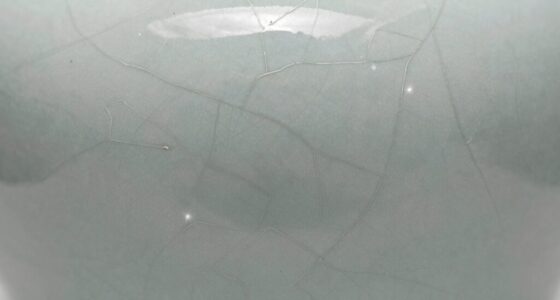

The Significance of Even and Controlled Drying

Ensuring your pottery dries evenly and gradually is critical to preventing warping and cracking during firing. When drying is inconsistent, moisture pockets cause uneven stresses that can distort your piece. Controlled drying allows moisture to escape slowly, reducing the risk of surface decoration damage or glazing techniques from cracking. Proper drying guarantees the surface remains smooth and intact, preserving the details of your surface decoration and any applied glazes. Rushing the process or drying unevenly can result in warping, even if your clay was well prepared. Keep your pieces in a stable environment, cover them as needed, and avoid drastic temperature changes. This careful approach helps maintain the integrity of your surface decoration and guarantees a more predictable, successful firing outcome. Deaf Vibes

How Thickness and Shape Influence Warping

Your pottery’s wall thickness plays a vital role in how it warps during firing. Thicker areas tend to retain moisture longer and can cause uneven shrinking, leading to warping. Additionally, the shape you choose influences stress points, making some forms more prone to distortion than others. Proper water content and ensuring even thickness can help reduce warping during the kiln firing process. Controlling kiln temperature management also minimizes uneven stress and reduces warping risk. Being mindful of firing schedule can further improve outcomes by allowing gradual temperature changes that lessen stress buildup. Paying attention to thermal expansion properties helps prevent uneven stress distribution that can cause warping.

Wall Thickness Effects

Thicker walls in pottery can considerably influence how the piece warps during firing, as they unevenly absorb heat and shrink. This uneven heat absorption can lead to warping, especially if the surface textures or glaze effects trap heat differently across the piece. Thicker sections cool slower and may develop stress points, increasing deformation risk. To minimize warping, keep wall thickness consistent and consider how shape impacts heat flow. Additionally, thermal expansion differences caused by varying wall thicknesses can further contribute to deformation during cooling. Managing material properties such as clay composition can also help reduce warping issues caused by thickness variations, emphasizing the importance of understanding clay characteristics for optimal firing outcomes. Properly controlling body porosity can also influence how heat is distributed throughout the piece, reducing warping tendencies. Being attentive to uniform wall thickness during shaping can significantly improve firing results and reduce deformation risks.

Form and Warping

The shape of a pottery piece considerably influences how it warps during firing, especially when combined with variations in thickness. A tall, narrow form may experience more warping if its surface texture is uneven or if glaze compatibility causes uneven heating. Thin areas cool and heat faster, increasing the risk of distortion, while thicker sections can resist warping but may develop stress points. The overall form determines how heat distributes across the piece, affecting warp potential. Smooth surface textures promote even heat absorption and reduce warping risks, whereas textured surfaces may trap heat unevenly. Choosing shapes that distribute heat evenly and maintaining consistent thickness helps control warping, especially when considering glaze compatibility, which influences surface behavior during firing. Additionally, understanding the kiln environment and how it impacts heat flow can be crucial for managing warping effectively. Managing thermal expansion by controlling firing schedules can further minimize stress and distortion in various shapes.

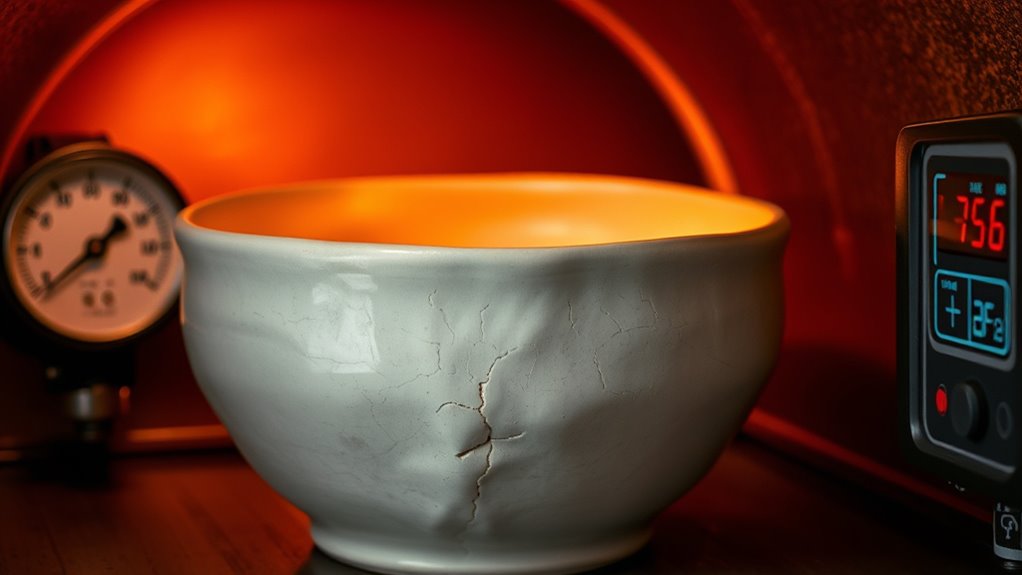

Understanding Firing Schedules and Ramp Rates

Understanding firing schedules and ramp rates is essential to preventing warping in pottery. Your firing schedule controls how quickly the kiln heats and cools, directly affecting glaze effects and overall aesthetic considerations. A rapid increase in temperature can cause uneven expansion, leading to warping or cracking. Conversely, a slow, controlled escalation allows the clay and glaze to mature uniformly, preserving shape and surface quality. Adjusting ramp rates based on the thickness of your pieces and glaze composition helps guarantee consistent results. Pay attention to how your kiln responds during different phases, especially during critical transitions like glaze maturation. By mastering your firing schedule, you gain more control over the final appearance, reducing warping risks while achieving your desired glaze effects.

Managing Temperature Fluctuations During Firing

Managing temperature fluctuations during firing is vital because sudden changes can cause uneven expansion and contraction in your pottery. Sharp temperature shifts stress the clay and glaze, increasing warping risk. To prevent this, monitor your kiln closely and follow a consistent firing schedule, avoiding rapid ramp rates. Ensure your kiln is well-maintained; faulty elements or thermocouples can cause temperature inconsistencies. Check glaze compatibility before firing, as incompatible glazes may crack or craze when exposed to uneven heat. Use a reliable kiln sitter or controller to help maintain steady temperatures. Proper kiln maintenance and controlled heating cycles help minimize fluctuations, protecting your pottery from warping and guaranteeing a more uniform, successful firing.

The Role of Support Structures and Shelf Placement

Your shelf placement and support choices directly impact how pottery warps during firing. Ensuring proper spacing and selecting the right support materials help keep pieces stable and prevent warping. Using consistent placement techniques also contributes to even heat distribution and better results. Additionally, understanding how materials and fuel interact during firing can influence warp prevention strategies.

Proper Shelf Spacing

Proper shelf spacing is crucial for preventing warping during kiln firing, as it guarantees even heat distribution and airflow around each piece. When spacing shelves correctly, you avoid uneven heating that can cause distortions. Make certain that your pottery’s glaze compatibility is considered; some glazes require specific temperature ranges and airflow conditions. Maintaining appropriate gaps allows the kiln atmosphere to circulate freely, reducing hot spots and temperature fluctuations that lead to warping. Avoid overcrowding shelves, which can trap heat and hinder airflow. Use consistent spacing to promote uniform heating, especially for large or complex pieces. Proper shelf support structures are essential to maintain consistent spacing and prevent shifting during firing. Ensuring that shelves are properly supported helps maintain consistent spacing and prevents accidental shifts that could cause uneven heating or warping. Proper shelf placement ultimately supports the kiln’s ability to achieve a balanced, stable atmosphere, minimizing warping risks and ensuring your pottery comes out correctly shaped.

Support Material Choices

Choosing the right support materials is essential to ensuring your pottery remains stable during firing. Support structures must withstand high temperatures without contaminating glazes or compromising glaze compatibility. The firing atmosphere also influences support choice; oxidation or reduction atmospheres can react differently with materials. Use kiln shelves made of kiln-formed glass or fireclay, compatible with your glazes and firing environment. The following table helps you select suitable support materials:

| Material | Glaze Compatibility | Firing Atmosphere |

|---|---|---|

| Kiln Shelf | High, non-reactive | Oxidation, reduction |

| Support Posts | Stable, inert | Suitable for high temps |

| Kiln Wash | Protects shelves, inert | Compatible with atmosphere |

| Firebrick | Insulative, stable | Suitable for various atmospheres |

Consistent Placement Techniques

Consistent placement of pottery on kiln shelves is essential for achieving even firing and preventing warping. When you arrange your pieces carefully, you allow heat to circulate uniformly, reducing stress that can cause warping. Be mindful of glazing techniques, ensuring no thick spots or pooling that can lead to uneven expansion. Surface decoration should be applied evenly, so it doesn’t create uneven weight distribution. Place taller or more fragile items on stable support structures to prevent shifting during firing. Keep pieces spaced adequately to avoid glaze drips or surface decoration from touching and sticking together. Proper placement helps maintain shape integrity, especially for pieces with detailed surface decoration or layered glazes. Developing a consistent placement technique is a key step toward successful, warp-free pottery firing. Additionally, understanding the thermal expansion properties of your clay and glaze combinations can help prevent warping during the firing process. Using consistent placement techniques also minimizes the risk of uneven heating, which is crucial for achieving uniform results. Paying attention to kiln loading methods can further improve heat distribution and reduce warping risks.

Recognizing and Correcting Common Warping Patterns

Warping patterns often reveal themselves early in the firing process, making it essential to recognize them before they become difficult to correct. Common shapes like warping edges, bowing sides, and twisting bases signal specific issues. These patterns can result from uneven heating, improper drying, or glaze interactions during firing. To identify them, observe your pottery during the initial stages of the kiln cycle. Use this table to understand their meanings:

| Pattern | Possible Cause | Correction Tip |

|---|---|---|

| Warped edges | Uneven drying or heating | Ensure uniform drying and heating |

| Bowed sides | Excessive moisture or glaze shrinkage | Adjust drying or glaze thickness |

| Twisted bases | Uneven kiln temperature or fit | Check kiln calibration and fit |

| Cracks from warping | Rapid temperature change | Fire gradually, control ramp rates |

| Distorted surface | Decorative techniques or glaze interactions | Use compatible glazes and techniques |

Being aware of firing techniques can also help prevent warping, as proper method selection influences the final shape.

Tips for Post-Firing Repairs and Preventative Measures

After identifying warping patterns early in the firing process, addressing issues promptly can save your pottery from permanent damage. If warping occurs, you can often perform post-firing repairs by carefully re-wetting and gently reshaping the clay texture before it cools completely. For minor warps, applying controlled heat or steam can help relax the clay and reduce distortion. Keep in mind that glaze effects may influence how warping appears; some glazes can emphasize or conceal uneven surfaces. To prevent future warping, consider incorporating thickening agents or additives that improve clay stability and reduce shrinkage during firing. Always handle your pottery carefully after firing, and store pieces in a stable environment to minimize stress. These steps can help maintain your pottery’s shape and enhance its overall durability.

Frequently Asked Questions

Can Using Different Clay Bodies Reduce Warping Issues?

Using different clay bodies can help reduce warping, as clay composition considerably impacts how your piece responds to firing temperature. Some clay types are more stable and less prone to warping during the firing process. By choosing clay with a suitable composition for your firing temperature, you can minimize warping. Always test new clay bodies and adjust your firing schedule to ensure the best results and prevent warping issues.

How Does Humidity During Storage Affect Clay’s Warping Potential?

High humidity during storage increases your clay’s warping potential by adding excess moisture, making it more prone to uneven drying and deformation. Low humidity, on the other hand, helps maintain consistent moisture levels, reducing warping risks. To minimize these effects, keep your clay in controlled storage conditions—avoid damp or overly dry environments. Consistent storage conditions equal consistent results, helping you create stable, well-shaped pottery every time.

Does Adding Grog or Other Additives Prevent Warping?

Adding grog or other additives can help prevent warping by improving clay’s stability during firing. Grog benefits include increased strength and reduced shrinkage, which minimizes deformation. The additive effects create a more balanced body that resists uneven expansion. You should consider incorporating grog into your clay mixture, especially for larger or thinner pieces, to enhance consistency and prevent warping during the kiln process.

How Do Different Kiln Atmospheres Influence Warping?

Different kiln atmospheres, like oxidation and reduction, influence warping by affecting how the clay and glazes mature. In oxidation, ample oxygen ensures even firing, reducing warping risks. Reduction atmospheres limit oxygen, causing chemical changes that can lead to uneven shrinkage. By controlling atmospheric conditions carefully, you can mitigate warping. Use atmospheric control to maintain consistent firing environments, preventing uneven stresses that cause your pottery to warp during the kiln process.

Can I Predict Warping Tendencies Based on My Pottery Design?

You can often predict warping tendencies by examining your pottery design, especially in relation to design symmetry and wall thickness. Uneven or asymmetrical shapes, along with inconsistent wall thickness, increase warping risks during firing. To minimize this, aim for balanced, symmetrical designs and uniform wall thickness. These adjustments help your piece withstand thermal stresses, making warping less likely and ensuring a more stable final product.

Conclusion

By understanding what causes warping and controlling these factors, you can create more stable, beautiful pottery. Sometimes, it’s a simple coincidence — like a perfect drying environment or a well-timed firing schedule — that makes all the difference. Keep experimenting, stay attentive to your process, and you’ll notice your pieces stay true to your vision. After all, a little awareness and care can turn a warped piece into a perfect masterpiece.