Clay cracks during drying because moisture moves from the interior to the surface too quickly, causing uneven shrinkage. When the outer layer dries faster, it pulls away from wetter inner layers, creating internal stress that leads to cracks. Poor drying practices, temperature fluctuations, and clay composition can all heighten this issue. To prevent this, careful control of drying conditions and understanding clay’s behavior are essential—if you want to uncover more, keep exploring the causes behind cracking.

Key Takeaways

- Rapid or uneven drying causes surface shrinkage and internal stress, leading to cracks.

- Excess moisture migration from interior to surface creates tension and surface fractures.

- Temperature fluctuations induce thermal expansion, stressing the clay during drying.

- Improper clay composition or additives can increase shrinkage and crack susceptibility.

- Handling or drying too quickly prevents even moisture loss, resulting in cracks.

The Role of Moisture Movement in Clay

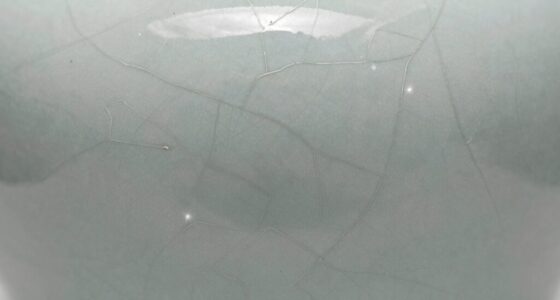

Moisture movement within clay is a key factor that causes cracks to form. When clay dries, moisture migration occurs from the interior to the surface, leading to uneven drying. As moisture escapes, the clay experiences shrinkage, known as clay shrinkage. This shrinkage isn’t uniform; the outer layer dries faster than the inside, creating stress. These internal stresses build up because the shrinking surface pulls away from the wetter, less-shrunk interior. The more moisture migration happens, the greater the shrinkage and stress become. Over time, this tension exceeds the clay’s strength, causing cracks to develop. Understanding moisture movement helps you grasp why cracks form during drying, highlighting the importance of controlling moisture loss to prevent damage. Innovative European Cloud Servers can offer sustainable solutions to monitor and optimize moisture control in industrial processes. Additionally, implementing proper drying techniques can significantly reduce the risk of cracking by promoting even moisture evaporation and managing clay shrinkage more effectively.

How Differential Drying Causes Cracks

When drying occurs unevenly across the surface of clay, it creates a condition known as differential drying. This uneven moisture loss causes the outer layer to shrink faster than the interior. As a result, surface tension increases, pulling the outer edges inward and stressing the material. Simultaneously, thermal expansion from temperature differences amplifies internal stress, leading to cracks. Here’s a breakdown:

| Effect | Cause | Result |

|---|---|---|

| Surface tension | Rapid moisture evaporation | Cracks form as surface pulls inward |

| Thermal expansion | Uneven temperature changes | Internal stress causes fractures |

| Differential drying | Unequal drying rates | Cracks develop across the surface |

This combination of surface tension and thermal expansion makes cracks inevitable when drying isn’t uniform. Proper moisture control can help minimize these issues during the drying process. Additionally, understanding the drying process in detail can lead to better techniques for preventing cracks. Recognizing the importance of even drying allows artists to develop more effective methods for drying clay without damaging the final piece. Moreover, implementing slow drying methods can significantly reduce internal stresses that cause cracking. Developing an awareness of clay composition and how it influences drying behavior can further improve outcomes and reduce defects.

The Impact of Clay Composition and Additives

The composition of clay and the additives you incorporate considerably influence how the material reacts during drying and firing. Clay mineralogy determines its shrinkage rate, porosity, and flexibility, affecting crack formation. For example, high kaolin content creates a more stable, less prone-to-crack piece, while illite-rich clay shrinks more unevenly. Additive effects also play a vital role; organic materials or grog can reduce shrinkage stress, making drying safer. Conversely, certain additives may alter the clay’s plasticity or drying behavior, increasing crack risk if not used properly. Understanding your clay’s mineralogy helps you select suitable additives and adjust your process accordingly. Ultimately, controlling composition and additive effects allows you to minimize cracking and achieve stronger, more durable finished pieces.

Common Mistakes That Lead to Cracking

Missteps in handling and preparing clay often lead to cracking issues. One common mistake is uneven drying caused by poor air circulation, which can create stress points from thermal expansion. To avoid this, make sure good airflow around your piece, but don’t rush the process. Second, rushing the initial drying stage increases the risk of cracks due to rapid temperature changes and uneven contraction. Additionally, controlling moisture levels throughout the drying process is essential for preventing stress buildup. Finally, handling the clay while it’s too wet or too dry can cause stress and cracks as the material shrinks unevenly. Be patient and monitor moisture levels carefully. Recognizing that fluctuations in temperature and air circulation can accelerate thermal expansion and contraction, leading to cracks, is crucial. Paying attention to these factors helps prevent common mistakes that cause cracking. Additionally, understanding the importance of proper drying techniques can significantly reduce the risk of damage. Incorporating controlled airflow management during drying can further minimize stress points and cracking.

Strategies to Prevent Cracks During Drying

To prevent cracks during drying, you need to control the environment carefully. Maintain consistent temperature control to slow down evaporation and reduce stress on the clay. Proper mold design also helps by allowing even moisture release and minimizing pressure points. Consider the following strategies:

| Strategy | Benefit |

|---|---|

| Use gradual drying | Prevents uneven shrinkage and cracking |

| Optimize mold design | Ensures even moisture distribution and stress relief |

| Control ambient temperature | Maintains consistent drying conditions |

Ensuring proper ventilation helps to regulate humidity and temperature levels, further reducing the risk of cracks. Additionally, monitoring clay moisture content throughout the drying process is crucial for early detection of potential cracking issues. Adjust your drying process based on these factors, and you will markedly reduce the risk of cracks. Environmental conditions such as humidity and airflow can greatly influence the drying outcome, so managing these factors is essential for a crack-free finish. Consistent temperature control and thoughtful mold design are key to achieving a crack-free finish. Being aware of environmental factors can help you fine-tune your drying environment for optimal results. Regularly checking moisture levels can help you make timely adjustments to prevent stress buildup that leads to cracking.

Frequently Asked Questions

Can Environmental Humidity Affect Clay Drying and Cracking?

Yes, environmental humidity impacts how clay dries and cracks. High humidity slows evaporation, causing uneven drying that increases the risk of cracking. Conversely, low humidity speeds up moisture loss, which can also lead to cracks if the surface dries too quickly. You should consider environmental factors like humidity to control the drying process better, ensuring your clay dries evenly and reduces the chances of cracking.

How Does Clay Thickness Influence the Likelihood of Cracking?

You’ll find that thicker clay pieces are 60% more prone to cracking because uneven drying causes stress. When clay isn’t uniform in thickness, it dries unevenly, leading to cracks. Thinner, uniform clay dries faster and reduces stress, preventing cracks. So, for smooth, crack-free projects, keep your clay layer even and avoid overly thick sections. This guarantees a more controlled drying speed and less risk of cracking.

Are Certain Clay Types More Prone to Cracking Than Others?

Yes, certain clay types are more prone to cracking because of their composition and firing temperature needs. For example, earthenware clay, with its high silica content, shrinks more during drying, increasing crack risk. Meanwhile, stoneware or porcelain, which require higher firing temperatures, tend to be sturdier once fired. You should choose a clay type matching your project’s firing temperature and understand its composition to minimize cracking.

What Role Do Temperature Fluctuations Play During Drying?

Temperature fluctuations considerably influence clay cracking during drying. As temperatures change, thermal expansion causes clay particles to shift and stress, leading to cracks. Sudden shifts can also disrupt moisture migration, trapping water inside or causing uneven drying. You should keep drying conditions stable, avoiding rapid temperature changes, to minimize these stresses. Consistent, moderate heat encourages even moisture migration and reduces the risk of cracking in your clay projects.

Can Improper Storage After Drying Cause Additional Cracking?

Yes, improper storage can cause additional cracking in your dried clay. Storage mishaps like exposing your piece to extreme temperature changes, high humidity, or rough handling can weaken its structure. When you don’t store your clay properly, it’s more vulnerable to stress and cracks over time. To prevent this, handle your piece carefully and store it in a stable, controlled environment, avoiding sudden shifts that could lead to new cracks.

Conclusion

Remember, cracking isn’t a sign of failure but a natural part of drying clay. By understanding moisture movement and drying techniques, you can minimize those unwanted cracks. It’s easy to think you need perfect conditions all the time, but even beginners make mistakes—what matters is learning and adjusting. So, don’t get discouraged if cracks appear; use them as a guide to improve your skills and create beautiful, crack-free pieces next time.