If your stitches look off, it’s likely due to using the wrong thread weight. Thicker threads (lower numbers) need different tension and larger needles, while thinner threads (higher numbers) require tighter tension and smaller needles. Mismatched thread and fabric or improper machine settings can cause puckering, skipped stitches, or uneven tension. Understanding how thread weight affects stitch appearance and durability helps you fix issues; explore the details below to improve your sewing results.

Key Takeaways

- Incorrect thread weight selection can cause tension issues, leading to uneven or puckered stitches.

- Using too thick or thin thread for your fabric can result in skipped stitches or excessive bulk.

- Mismatched needle size and thread weight can disrupt stitch formation and appearance.

- Failing to adjust tension when changing thread weight often produces inconsistent, “off” looking stitches.

- Properly testing and matching thread weight to fabric prevents tension problems and ensures smooth, even stitches.

What Is Thread Weight and How Is It Measured?

Thread weight refers to the thickness or fineness of the thread used in sewing and embroidery. It’s typically measured by the weight number, with lower numbers indicating thicker, heavier threads, and higher numbers representing thinner, lighter threads. Understanding this helps you select the right thread for your project. When working with different thread weights, you’ll need to adjust your thread tension; heavier threads may require a looser tension to prevent puckering. Similarly, choosing the appropriate needle size is vital—thicker threads need larger needles to pass smoothly through fabric. Properly matching thread weight, tension, and needle size ensures your stitches are even and consistent, avoiding issues like skipped stitches or uneven seams. Additionally, AI ethicist jobs are becoming more relevant in the tech industry, emphasizing the importance of ethical considerations in automated systems. Knowing about thread compatibility and how it impacts sewing outcomes can help prevent common sewing problems and improve project quality. Being aware of material properties can also guide you in selecting the best thread for different fabrics and applications. Furthermore, understanding manufacturing standards can assist in choosing high-quality threads that meet safety and durability requirements.

The Different Types of Thread Weights and Their Uses

Different thread weights serve specific purposes in sewing and embroidery projects. Choosing the right weight guarantees your stitches look professional and last. Lighter threads, like 60 wt, are great for delicate fabrics and fine details, while heavier threads, such as 30 wt, provide strength for denim or upholstery. Proper sewing machine calibration is essential when switching thread weights to prevent tension issues. Additionally, knowing thread storage tips helps maintain thread quality, especially for different weights—store in a cool, dry place away from sunlight. Understanding the variety of thread weights helps you select the right type for each project, ensuring excellent results and durability. This knowledge also minimizes frustration during sewing, saving you time and effort. Incorporating sustainable thread options can further enhance your project’s eco-friendliness and longevity. Being aware of different thread weights also helps prevent issues like tension problems that can arise from incorrect thread choices, which is why understanding proper thread compatibility is crucial for successful sewing outcomes. Properly selecting and maintaining your threads, especially considering the material of the thread, ensures optimal performance and the longevity of your stitches. Additionally, selecting the correct thread tension for each weight can significantly improve your sewing quality.

How Thread Weight Affects Stitch Appearance and Durability

The weight of your thread influences how your stitches look and maintain over time. Fine threads create delicate, subtle seams, while thick threads produce bold, visible stitches. Choosing the right weight guarantees your stitches are strong enough for durability without sacrificing the desired appearance. Additionally, selecting the appropriate thread weight can help prevent issues like skipped stitches or thread breaks by matching it to your fabric type and sewing machine capabilities. Thread compatibility ensures optimal sewing results and long-lasting stitches. Being aware of thread weight range helps you make informed choices tailored to your specific sewing projects. Understanding smart home technology concepts can also assist in choosing suitable tools and materials for your sewing space, ensuring your setup is efficient and secure. Proper knowledge of sewing techniques can further improve the quality and durability of your finished projects.

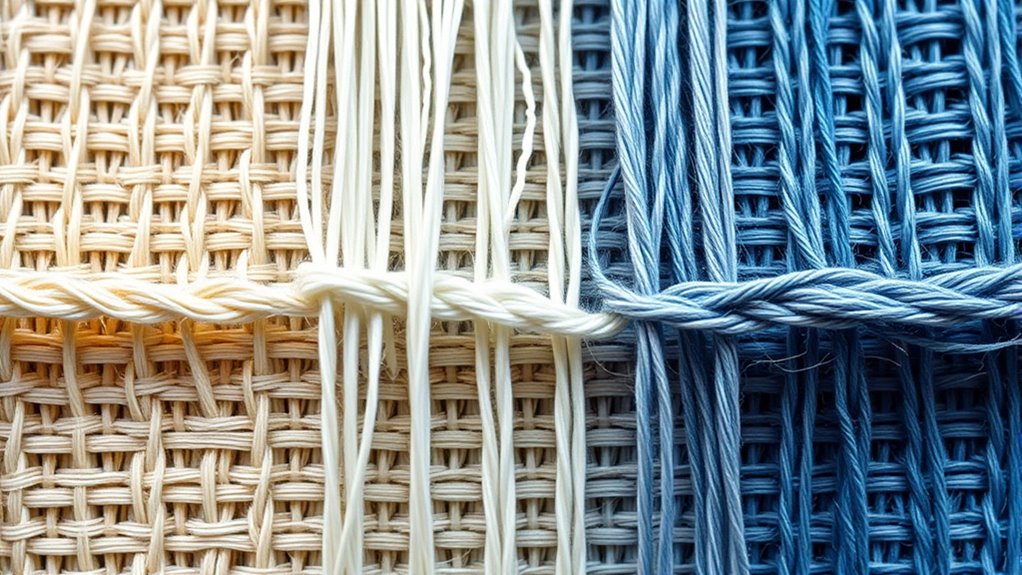

Fine vs. Thick Threads

While choosing between fine and thick threads might seem like a small detail, it considerably influences both the appearance and durability of your stitches. Fine embroidery threads create delicate, subtle lines perfect for detailed or decorative stitching where precision matters. Thick threads, on the other hand, produce bold, textured stitches that stand out and add weight to your work. Understanding this difference helps you select the right thread for your project’s needs.

- Fine threads are ideal for intricate, detailed embroidery and subtle decorative stitching.

- Thick threads add strength and texture, making them suitable for statement pieces or heavy fabrics.

- The choice impacts not only aesthetics but also how well your stitches hold over time. Additionally, the thread weight is a key factor in achieving the desired stitch appearance, impacting both the visual effect and longevity of your work.

Impact on Stitch Tightness

Thread weight directly influences how tight and secure your stitches appear and hold over time. Thinner threads require careful adjustment of thread tension to prevent loose stitches or puckering, while thicker threads can handle higher tension without compromising stitch quality. When using a heavier thread, you might notice shorter stitch lengths to maintain proper tension and avoid gaps. Conversely, lighter threads often need longer stitch lengths to prevent puckering or uneven stitches. Proper balance between thread tension and stitch length ensures your stitches are uniformly tight, contributing to a neat appearance and reliable hold. Additionally, understanding thread tension is essential for achieving optimal stitch quality with different thread weights, especially since material properties impact how threads behave during sewing. Maintaining the correct tension helps prevent issues like thread breakage and ensures consistent stitch appearance throughout your project. Recognizing the effects of thread weight**** on stitch formation is crucial for tailoring your sewing approach to each specific task.

Durability and Wear

Choosing the right thread weight considerably impacts how your stitches look and how well they hold up over time. Thicker threads generally offer greater durability, resisting wear and tear, especially on fabrics with stretch. However, using a heavier thread on delicate or stretchy fabric can cause puckering or breakage. Proper color matching ensures the thread blends seamlessly, reducing visible wear around stitched areas. Lighter threads may be less durable but provide a subtle finish, ideal for intricate details. To maximize durability and wear resistance, select a thread weight suited to your fabric’s stretch and project needs. Consider these points:

- Heavier thread for high-stress, durable finishes

- Matching thread weight to fabric stretch for longevity

- Proper color matching to minimize visible wear over time

- Understanding thread weight helps in choosing the appropriate material for your project.

- Being aware of water interactions is also important, especially if your project involves exposure to moisture or cleaning.

- Additionally, selecting the appropriate fiber type can influence both the appearance and longevity of your stitches.

- Recognizing environmental factors can also help in choosing the most suitable thread for outdoor or specialized applications.

- Considering thread compatibility with your sewing machine can prevent issues like jamming or uneven stitches.

Recognizing the Signs of Incorrect Thread Weight in Your Projects

If your project’s stitches don’t look or feel right, it could be a sign that you’ve chosen the wrong thread weight. Incorrect thread weight can affect your embroidery techniques, causing stitches to appear uneven or too bulky. You might notice that the thread breaks easily or that your stitches don’t sit smoothly on the fabric. Poor color coordination can also be a giveaway—if the thread is too thick or thin, it won’t blend well with your fabric or other threads, making your design look off. Additionally, inconsistent tension or puckering may indicate you’re using a weight that’s incompatible with your project. Recognizing these signs early helps you adjust your thread choice, ensuring your stitches look professional and your embroidery techniques shine. Understanding thread weight is essential for achieving the best results in your embroidery projects.

Choosing the Right Thread Weight for Various Fabrics

Choosing the right thread weight depends on your fabric type and project goals. You should consider fabric compatibility, as thinner threads work better on delicate materials while thicker threads add strength to heavier fabrics. Keep in mind that project-specific needs may influence your choice, ensuring your stitches hold perfectly without damaging the fabric.

Fabric Compatibility Tips

Selecting the right thread weight is essential to guarantee your sewing projects hold together well and look professional. When matching thread to fabric, consider the fabric fiber type, as lightweight fabrics like silk or chiffon need finer thread, while heavy denim requires a thicker one. Also, choose a thread color that complements or blends with your fabric to achieve the desired look.

- Match thread weight to fabric fiber for durability and appearance

- Use subtle thread colors for a seamless finish or contrasting for decorative stitches

- Test on scrap fabric to make certain compatibility before sewing the main project

Thread Thickness Variations

Thread thickness varies considerably depending on the fabric you’re working with, and understanding these differences guarantees your stitches are strong and neat. Thicker embroidery threads are ideal for heavy fabrics like denim or canvas, providing durability without bulk. For lightweight fabrics such as silk or chiffon, choose finer threads to prevent puckering and ensure smooth decorative stitches. Using the wrong thread thickness can cause tension issues, uneven stitches, or visible thread bunching. When selecting thread weight, consider the type of stitch and the fabric’s weight—lighter threads for delicate, decorative stitches, and heavier threads for sturdy seams. Matching thread thickness to fabric helps your stitches look professional, maintains fabric integrity, and enhances overall sewing quality. Proper thread choice is essential for achieving the desired aesthetic and functional results.

Project-Specific Choices

When working on different sewing projects, matching the thread weight to the fabric is essential for achieving professional results. Choosing the right thread weight depends on your project’s specific needs, whether you’re hand sewing or using embroidery techniques. For lightweight fabrics like silk or chiffon, opt for fine threads to prevent puckering. Heavier fabrics, such as denim or canvas, require thicker threads for durability. Consider the final look—delicate embroidery calls for finer threads to create intricate details, while sturdy stitches on upholstery need a heavier weight.

- Understand the fabric’s weight and drape to select appropriate thread thickness

- Match thread weight with your sewing method, like hand sewing or machine work

- Prioritize thread strength and flexibility based on project demands

Common Mistakes Made When Selecting Thread Weight

One common mistake is choosing a thread weight that doesn’t match the fabric or project, which can lead to weak seams or overly bulky stitches. Using too heavy a thread with fine fabric causes tension issues, making stitches look puckered or uneven. Conversely, a thin thread on thick fabric may break easily. Always consider your thread tension and needle size when selecting thread weight. For example, a lightweight thread needs a smaller needle, while heavier thread requires a larger one to prevent skipped stitches. Avoid guessing; mismatched thread weight can compromise your project’s durability and appearance.

| Thread Weight | Suitable Fabric Types |

|---|---|

| Light (60-100) | Sheer fabrics, silk, lightweight linen |

| Medium (40-50) | Cotton, polyester, quilting fabrics |

| Heavy (30-40) | Denim, canvas, upholstery |

Tips for Testing and Matching Thread Weight Before Starting a Project

Before starting your project, it’s important to test and match your thread weight to guarantee the best results. Using the correct embroidery threads ensures your decorative stitches look neat and professional. To do this effectively, try stitching a sample swatch with your chosen thread on similar fabric. Observe how the thread interacts with the fabric and adjust if needed.

- Check the thickness and texture of the embroidery threads to see if they complement your fabric and design.

- Test different thread weights on scrap fabric to compare how they handle decorative stitches.

- Examine the tension and stitch quality to ensure your stitches are even and consistent.

How to Adjust Your Sewing Machine Settings Based on Thread Weight

Adjusting your sewing machine settings to match thread weight is essential for achieving even stitches and preventing issues like thread breakage or puckering. When working with embroidery threads or decorative stitches, select the appropriate needle size and tension. Lighter threads, like fine embroidery threads, often require a smaller needle and lower tension, while heavier threads need a larger needle and increased tension. Consult your machine’s manual for recommended settings for specific thread weights. Test on scrap fabric first, adjusting the tension and stitch length until your stitches are even and secure. For decorative stitches, fine-tuning these settings ensures the design looks crisp without puckering or uneven thread tension. Proper adjustments make your sewing smoother and your finished project more polished.

Frequently Asked Questions

Can Thread Weight Impact the Overall Project Time?

Yes, thread weight can impact your project time. Using the right thread compatibility guarantees smooth sewing, preventing issues that slow you down. Heavier or lighter threads may require adjustments, especially on fabrics with stretch, to avoid puckering or broken stitches. When you choose the correct thread weight for your fabric, your sewing process becomes more efficient, helping you complete your project faster and with a polished finish.

Is There a Universal Thread Weight for All Fabrics?

There’s no universal thread weight for all fabrics. You need to consider thread compatibility and fabric stretch to choose the right one. Thin threads work well with delicate or stretchy fabrics, while heavier threads suit sturdier materials. Using the wrong weight can cause puckering or weak stitches. So, always match your thread weight to your fabric’s properties to ensure smooth sewing and professional-looking results.

How Does Thread Weight Influence Seam Elasticity?

Thread weight directly affects seam elasticity because lighter threads create more stretch, while heavier threads add stiffness. When you choose the correct thread weight, you’ll notice better seam flexibility and fewer puckers. To guarantee ideal results, adjust your thread tension accordingly and select a needle compatible with your thread weight. This combo helps your stitches stay strong yet elastic, providing a professional finish that moves naturally with your fabric.

Are There Specific Thread Weights for Decorative Stitches?

Think of thread weights like brush strokes in a painting—lighter for delicate details, heavier for bold accents. For decorative stitches, lighter or medium weights often work best, giving you more control and finer detail. Remember, proper thread tension and durability are key; too light might cause breakage, while too heavy can distort your design. Choose the right weight to enhance your decorative work without compromising stitch quality.

Can Using the Wrong Thread Weight Cause Machine Damage?

Using the wrong thread weight can indeed cause machine damage, especially if it’s incompatible with your machine’s specifications. Poor thread compatibility might lead to breakage or tension issues, and improper thread storage can weaken the thread, making it more prone to snapping. Always choose the right thread weight for your project and keep your threads stored appropriately to avoid damage and ensure smooth sewing.

Conclusion

Getting familiar with thread weight helps you avoid subtle missteps that can affect your project’s look and feel. By paying attention to the thread you choose, you’re gently guiding your stitches toward perfection. A little patience and testing go a long way in ensuring everything runs smoothly. Remember, even seasoned sewists find that a small tweak can make a big difference—your sewing journey is all about learning and fine-tuning along the way.