Your wire wraps can unravel if the wire isn’t suited for your project or if the wraps aren’t secured tightly, especially at the start and end. Using soft or unsuitable materials, poor tension, or sloppy wrapping contribute to instability. To prevent this, master proper tucking, crimping, and consider adding loops or using glue to lock everything in place. Keep tension consistent and perform regular checks—more tips to help you create secure, lasting wraps await as you explore further.

Key Takeaways

- Use appropriate wire materials like copper or stainless steel to prevent weakening and unraveling over time.

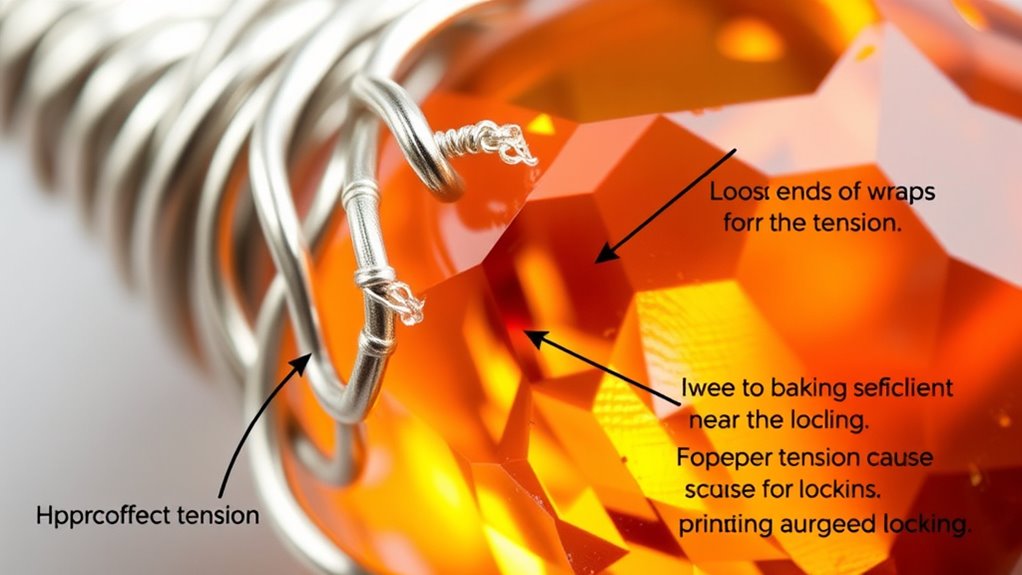

- Maintain consistent tension during wrapping and finish with tight, secure wraps to lock everything in place.

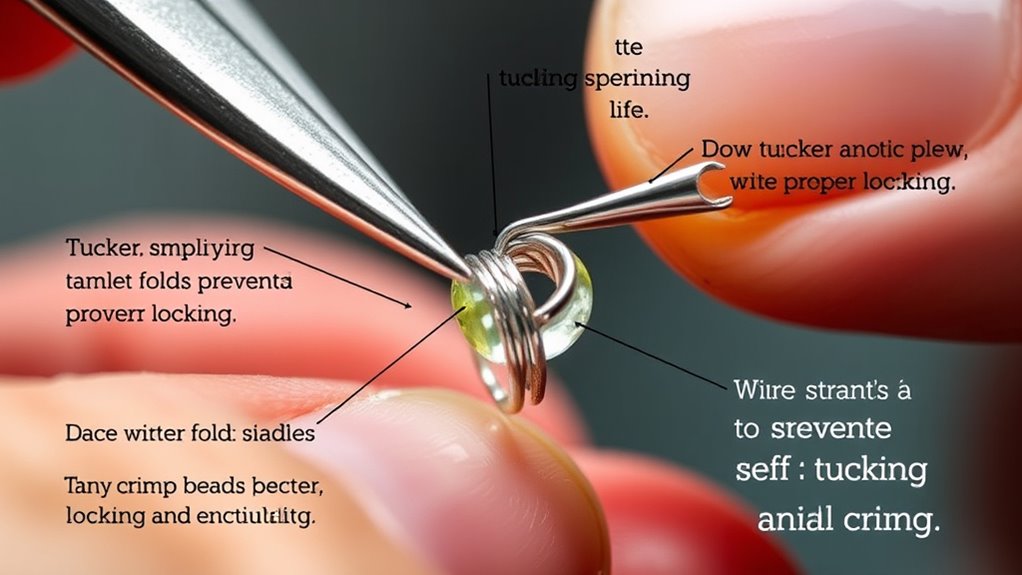

- Properly tuck and crimp excess wire to prevent slippage, ensuring tucks are flush and firmly pressed.

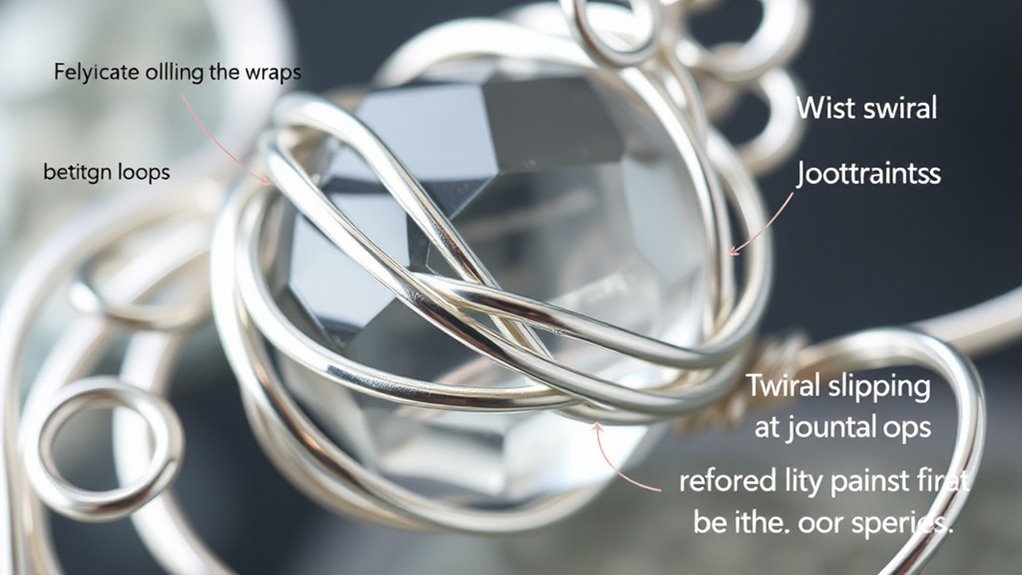

- Reinforce critical points with additional wraps, loops, or decorative crimps for extra stability.

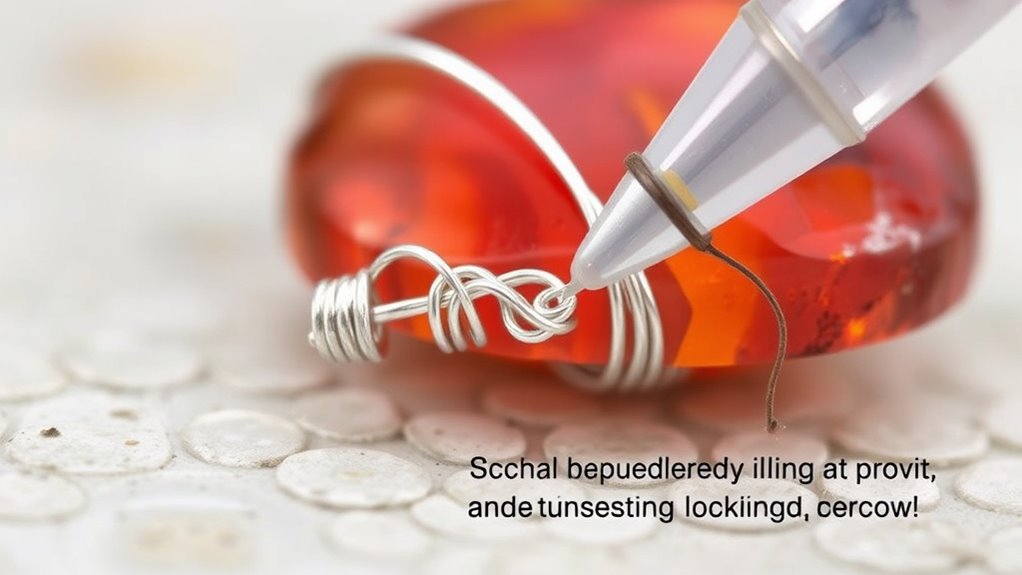

- Apply a strong adhesive or epoxy at ends and critical areas to lock wraps and prevent unraveling from environmental factors.

Common Causes of Wire Wrap Unraveling

Wire wraps can start unraveling for several straightforward reasons. One common cause is poor wire material selection; using a wire that’s too soft or too stiff can compromise the wrap’s stability. Soft wires may bend easily and lose their grip, while stiff wires can crack or resist forming snugly. Additionally, neglecting wrapping aesthetics plays a role—sloppy or uneven wraps don’t hold as well and are more prone to slipping apart over time. If you don’t secure the wire properly or if the wire is incompatible with your design, unraveling becomes more likely. Temperature fluctuations and exposure to moisture can weaken certain wire types, reducing their ability to stay tight. Paying close attention to wire choice and maintaining neat, consistent wrapping can help prevent unraveling before it starts. Considering the material properties of your wire can further ensure durability and long-lasting security. Moreover, understanding how paint sprayer maintenance impacts overall project quality can help you avoid issues that compromise your work’s integrity. Proper air purifier maintenance can also prevent dust and debris buildup that might interfere with your project’s cleanliness and durability.

Choosing the Right Wire Gauge and Material

Selecting the right gauge and material for your wire is key to guaranteeing a secure and durable wrap. Your choice of wire gauge affects flexibility and strength; thinner wire is easier to manipulate but may be prone to breaking, while thicker wire provides more support but can be harder to work with. When considering material, prioritize durability—materials like copper or stainless steel resist corrosion and maintain integrity over time. Softer metals like gold or silver are attractive but may require extra care to prevent unraveling. Proper wire gauge selection balances ease of wrapping with strength, reducing the risk of unraveling. Choosing a material with high durability ensures your wire wraps stay intact, even with regular handling or exposure to elements. Additionally, understanding contrast ratio can help you select wires that maintain their appearance under various lighting conditions. Being aware of wire flexibility can also guide your choice, especially for intricate or tight wraps that require more bendability. Incorporating wire consistency into your selection process can further enhance the overall stability of your jewelry pieces. Considering the environmental exposure your jewelry will face can also influence your choice of material, ensuring longevity in different conditions. To further improve the longevity of your wraps, consider selecting wires with oxidation resistance, especially for pieces that will be worn outdoors or in humid conditions.

Proper Techniques for Starting and Ending Wraps

To guarantee your wire wraps stay secure, you need to start with a firm, tight initial wrap. When ending, make sure to finish with tight wraps to lock everything in place. These techniques help prevent unraveling and give your work a professional finish. Incorporating proper techniques can make a significant difference in the durability of your wraps. Additionally, understanding jewelry measurements ensures your wraps fit correctly and stay secure. Using local automation principles can also help you develop consistent wrapping routines for better results. Regular practice and feedback can further enhance your technique mastery, leading to more reliable and professional-looking jewelry.

Secure the First Wrap

Starting your wire wrap securely sets the foundation for a stable and professional-looking piece. To do this, maintain proper starting tension by gently pulling the wire as you make your initial grip. This ensures the first wrap is snug without being too tight, which can cause damage or make adjustments difficult later. Use a firm but controlled grip to keep the wire steady as you begin wrapping around your component or mandrel. Focus on consistent tension to prevent loose or uneven wraps that could unravel. Your initial grip should be firm enough to hold the wire securely, but not so tight that it deforms or kinks. Properly securing the first wrap creates a strong base for the rest of your design, reducing the risk of unraveling later. Additionally, understanding the importance of proper tension control helps ensure your wraps stay tight and secure throughout your project. Being mindful of passive voice detection can also improve the clarity and strength of your instructions. Developing a steady hand and consistent technique is essential for achieving a professional finish and avoiding sloppy craftsmanship. Practicing these techniques regularly will help you develop a reliable wrapping method that enhances your jewelry-making skills.

Finish With Tight Wraps

Finishing your wire wrap with tight wraps guarantees your design stays secure and professional-looking. When ending a wrap, ensure each turn is snug against the previous one, especially around decorative patterns. This prevents gaps that could cause unraveling. Tight wraps also help maintain your design’s shape and stability, which is vital when working with color coordination. Matching wire colors or complementary shades enhances the overall look, but only if the wraps are secure. As you finish, wrap tightly and trim excess wire close to the final turn, then tuck the end neatly to avoid snagging. Properly finished wraps give your piece a polished appearance and prevent unraveling over time. Taking this extra step with secure wrapping techniques ensures your wire work remains durable and visually appealing. Additionally, practicing proper tension control during wrapping helps sustain consistent tightness throughout your design, further preventing unraveling. Consistent tension also helps achieve a uniform appearance, contributing to the overall professional quality of your piece. Developing technique consistency can significantly improve your results and help your designs last longer.

Securing Wraps With Effective Tucking and Crimping

Securing wire wraps effectively often hinges on proper tucking and crimping techniques. When you tuck the wire, use smooth, controlled twist techniques to guarantee the wire stays tight without damaging it. Proper twisting reduces the wire resistance, preventing weak points that could cause unraveling. After wrapping, fold or bend the excess wire neatly into the main wrap to lock it in place. Crimping is also essential; use pliers to firmly press down on the tucks, making sure they are secure and flush with the surface. Avoid over-crimping, which can weaken the wire, and under-crimping, which leaves the wrap loose. With careful tucking and crimping, your wraps will be more stable and less prone to unraveling over time. Additionally, understanding the importance of secure connections can help you achieve more durable results in your wire wrapping projects. Using proper tools designed for jewelry-making can further enhance the precision and stability of your wraps. Employing consistent technique ensures each wrap maintains the same tension and security throughout your project.

Using Additional Restraints Like Wraps or Loops

Adding wraps or loops around your wire can give extra stability and prevent unraveling. You can reinforce your work by applying multiple wraps or securing with loops at critical points. Using more than one restraint guarantees your wire stays tight and reduces the risk of slipping.

Reinforce With Wraps

To prevent wire wraps from unraveling, you can reinforce them by adding extra restraints like wraps or loops. Incorporating decorative patterns can also strengthen the design while adding visual interest. Use wire bending techniques to create small loops or twists around the main wrap, securing it firmly in place. These additional wraps act as barriers, holding the primary wire tight and resisting movement. Carefully position your wraps to evenly distribute tension, which helps maintain the integrity of your design. The key is to keep your wraps snug but not overly tight, so they don’t distort the shape. This method guarantees your wire remains secure, reduces the risk of unraveling, and enhances the overall durability of your jewelry or craft project.

Secure With Loops

When you want to guarantee your wire wraps stay firmly in place, creating loops is an effective technique. Decorative loops not only secure the wire but also enhance the wire wrap aesthetics, giving your piece a polished look. By forming small loops around the main wire, you add an extra layer of restraint that keeps the wrap from unraveling. These loops can be placed strategically along the wire to prevent movement and create visual interest. Keep the loops tight but neat, ensuring they don’t distort the overall design. Using loops as additional restraints helps lock the wire in place without sacrificing style. This simple step can make a significant difference in the durability and appearance of your finished wire wrap.

Use Multiple Restraints

Using multiple restraints, such as combining wraps and loops, substantially enhances the security of your wire wrap. By layering these techniques, you distribute tension more evenly, reducing unraveling risk. To maximize effectiveness, select the appropriate wire gauge, considering material durability—thicker wire offers strength, while durable materials resist wear. When adding loops or wraps, ensure they are tight and well-placed, locking other restraints in place. This method makes your design less dependent on a single securing point, preventing slippage even with movement. Below is a helpful comparison:

| Restraint Type | Benefits |

|---|---|

| Wraps | Distribute tension, add strength |

| Loops | Lock wraps in place, prevent slipping |

| Multiple Restraints | Enhance security and durability |

| Material Choice | Improve longevity and robustness |

Combining these strategies ensures your wire wraps stay secure over time.

How to Lock Wraps With Jewelry Cement or Glue

If your wire wraps are starting to come loose, applying jewelry cement or glue offers an effective way to lock them in place. Choose from various adhesive options, such as epoxy, super glue, or jewelry-specific adhesives, depending on your project’s needs. Before applying, confirm the surfaces are clean and dry for the best bond. Use a small brush or toothpick to carefully place the glue on the wrapped areas, avoiding excess that could seep onto your design. Keep in mind curing times, which vary by adhesive; some may set in minutes, while others require several hours or overnight. Follow the manufacturer’s instructions precisely to ensure a secure, long-lasting hold. This simple step helps prevent unraveling and keeps your wire wraps intact.

Tips for Maintaining Tension During Wrapping

Maintaining consistent tension is essential for neat, secure wire wraps. Proper tension control ensures your wraps stay tight and prevent unraveling. Use your fingers to gently pull the wire as you wrap, keeping pressure even. Practice wrapping techniques like steady, even movements and avoid jerking. To help sustain tension, try anchoring the wire firmly against the work surface with your thumb. Keep your wraps close together without overlapping tightly—this balance makes for a professional finish. Below is a simple guide:

| Tip | Technique | Result |

|---|---|---|

| Use steady pressure | Keep tension uniform throughout | Tight, even wraps |

| Anchor wire early | Hold wire firmly, don’t slack | Prevents loosening |

| Practice wrapping | Repeat to build consistency | Improved tension control |

Master these tips to keep your wraps secure and flawless.

Regular Inspection and Maintenance for Longevity

Regular inspection and maintenance are essential to ensuring your wire wraps stay secure and last over time. Regularly check for loosened wraps or signs of wear. Use proper polish techniques to restore shine and smoothness, which helps prevent snagging. Keep your tools in good condition through consistent tool maintenance—sharpen and clean them regularly to ensure precise wraps. To maximize longevity, consider these steps:

Regularly inspect, polish, and maintain tools to ensure durable, secure wire wraps.

- Examine your wire wraps for any signs of unraveling or damage.

- Re-tighten loose wraps promptly.

- Polish the wire to maintain a smooth surface.

- Clean and maintain your tools to achieve consistent, accurate wrapping.

Consistent care prevents unraveling, extends the life of your wire work, and improves overall craftsmanship.

Frequently Asked Questions

What Are the Best Tools for Securing Wire Wraps?

To secure wire wraps effectively, you should use pliers like chain-nose and round-nose tools, which help you tighten and manipulate the wire precisely. Selecting the right wire gauge guarantees durability, while proper wrapping techniques, such as wrapping tightly and making secure loops, prevent unraveling. These tools and methods work together to lock your wire wraps firmly, giving your jewelry a professional finish and lasting strength.

How Do Temperature Changes Affect Wire Wrap Stability?

When temperatures fluctuate, your wire wraps can become unstable because of thermal expansion and material contraction. You might think it’s no big deal, but these changes can loosen your wraps over time. To keep them secure, use flexible wire or add a lock-tight coating. Temperature swings challenge your wraps, but proper materials and techniques help prevent unraveling, ensuring your jewelry stays intact no matter the weather.

Can Different Wire Coatings Improve Wrap Durability?

Yes, different wire coatings can enhance wrap durability. Coatings like enamel or polymer safeguard the wire from wear and environmental damage, reducing unraveling. Additionally, applying wrap reinforcement—such as twisting or adding a layer of protective material—further secures your wraps. Choosing the right wire coating and reinforcement method ensures your wraps stay tight and intact longer, especially in demanding conditions.

Is There an Ideal Number of Wraps to Prevent Unraveling?

You should aim for about three to five wraps to prevent unraveling, adjusting based on wire thickness and wrap tension. Thicker wire generally needs fewer wraps, while tighter tension helps secure the wrap. Keep consistent tension and avoid over-tightening, which can weaken the wire. Practice makes perfect—experiment with different numbers of wraps until you find the balance that keeps your wraps secure without damage.

How Do I Fix a Wire Wrap That Has Already Unraveled?

If your wire wrap has unraveled, don’t worry—you can fix it easily. Start by tightening the thread tension and re-wrapping along the original pattern. Secure the new wraps by wrapping a few extra turns around the previous ones, then tuck the ends neatly. Use pliers to gently press down and lock the wraps in place. This restores stability and helps prevent future unraveling.

Conclusion

By understanding these tips, you’ll prevent your wire wraps from unraveling and guarantee your jewelry stands the test of time, even through the sands of time like an ancient pharaoh’s tomb. Keep your tension steady, secure your ends properly, and don’t forget to give your piece a good inspection now and then. With care and patience, your wire wrapping skills will remain as steadfast as a knight’s armor, making your creations both beautiful and durable.