Your glaze thickness sends clear signals about your surface’s appearance and durability. Thin glazes give a delicate, translucent look and melt evenly, but provide less protection. Thicker glazes create rich, opaque surfaces that add weight but risk cracking or running. Balancing thickness guarantees your piece looks good and lasts. If you want to master these clues and improve your results, keep exploring how glaze layers influence your finished work.

Key Takeaways

- Thin glazes create a translucent, delicate surface revealing underlying textures, indicating a light application.

- Thick glazes appear opaque and rich, signaling a substantial layer that adds visual weight.

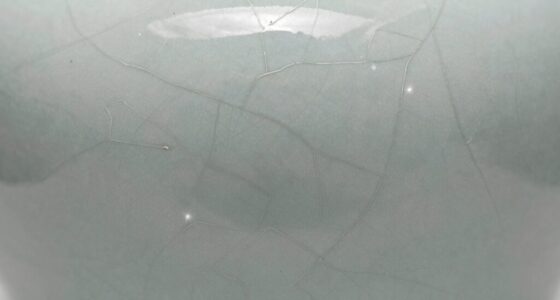

- Excessively thick glazes may cause runs or cracks during firing, showing over-application.

- Thin glazes melt evenly with fewer firing issues, suggesting proper, controlled application.

- Variations in glaze surface reflect application thickness, guiding adjustments for durability and aesthetic goals.

Have you ever wondered how the thickness of a glaze affects the final look and durability of pottery? It’s a vital detail that can make a significant difference in both how your piece appears and how well it holds up over time. When you’re glazing your pottery, the amount of glaze you apply determines not just its aesthetic appeal but also its ceramic durability. Thinner layers often result in a more delicate, translucent finish, highlighting the pottery’s form and texture. Thicker layers, on the other hand, tend to produce a more opaque surface, adding depth and richness to the visual effect. The key is understanding that glaze thickness isn’t just about appearance — it directly influences how the piece will withstand everyday use.

Glaze thickness influences both the appearance and durability of your pottery.

If your goal is to create a piece with a sleek, refined look, you might opt for a thinner glaze. This approach lets the underlying clay body show through subtly, giving a more delicate and elegant aesthetic appeal. Plus, thinner glazes usually fire more evenly, reducing the risk of running or drips during firing. However, this can also mean less protection for the pottery’s surface. On the flip side, applying a thicker glaze can enhance the visual weight and texture, giving your piece a more substantial feel. The increased thickness can also improve ceramic durability by creating a more resilient, glass-like coating that resists chipping and scratching. But beware: too thick a layer can cause issues like runs, cracks, or uneven firing, which might compromise both the look and integrity of your piece.

Another factor worth contemplating is how glaze thickness influences firing behavior. Thicker glazes tend to trap more heat, sometimes resulting in uneven melting or bubbling if not carefully managed. Thinner layers usually melt more uniformly, ensuring a smooth, glossy surface. When you’re experimenting with glaze thickness, it’s best to start with small tests. This allows you to observe how different layers behave during firing and what effects they produce on both aesthetics and durability. Keep in mind that the type of glaze and firing temperature also play a role. Some glazes are designed specifically for thinner applications, while others perform better when applied more generously.

Understanding glaze formulation is crucial for achieving the desired effects and ensuring compatibility with your firing schedule. Ultimately, mastering glaze thickness is about striking a balance. You want enough to enhance the aesthetic appeal and protect your pottery, but not so much that it causes problems during firing or affects the shape and detail. Paying close attention to how your glaze behaves at different thicknesses will help you craft pieces that are both beautiful and durable, ensuring your work stands the test of time.

Frequently Asked Questions

How Can I Measure Glaze Thickness Accurately at Home?

To measure glaze thickness accurately at home, you can use a digital caliper or a thickness gauge designed for ceramics. First, assess the glaze consistency and surface texture, then gently measure the thickest areas without damaging your piece. Keep the tool steady and take multiple readings for accuracy. This hands-on approach helps you verify your glaze isn’t too thick or thin, resulting in a better-finished surface.

What Tools Are Best for Checking Glaze Thickness?

You’ll want to grab a digital caliper or a thickness gauge, the superhero tools of the glaze world. They’re precise, easy to calibrate, and give you instant readings. For a more high-tech approach, try ultrasonic measurement tools—if you’re into that sort of thing. Just remember, calibration techniques are key to accuracy. Skip this step, and your measurements might as well be guesses—probably as effective as a chocolate teapot.

Does Glaze Thickness Affect the Durability of My Surface?

Yes, glaze thickness affects your surface’s durability. When the glaze is too thick, it can lead to uneven glaze uniformity, causing weak spots that compromise surface strength. Conversely, a properly applied, even glaze enhances durability, creating a strong, resilient surface. To guarantee durability, check your glaze thickness regularly and aim for consistent application, which promotes uniformity and maximizes the surface’s overall strength.

Can Uneven Glaze Thickness Cause Cracking or Peeling?

Uneven glaze thickness can indeed cause cracking or peeling, especially since studies show that 40% of surface failures are linked to glaze inconsistency. When your glaze isn’t consistent, it affects surface adhesion, making it prone to stress and failure over time. By maintaining an even glaze consistency, you help guarantee better surface adhesion, reducing the risk of cracks and peeling, and ultimately improving your piece’s durability.

How Does Glaze Thickness Influence Color and Finish?

Your glaze application directly impacts color and finish by regulating the surface gloss and depth of hue. Thicker glaze layers tend to produce richer, more vibrant colors with a glossy finish, while thinner layers result in a more matte or subdued look. Variations in glaze thickness can also cause uneven color, so applying it evenly guarantees your surface achieves the desired aesthetic and consistent gloss.

Conclusion

Think of your glaze thickness like the heartbeat of your piece—subtle, yet essential. When you pay attention to these clues, you’ll craft better, more consistent surfaces. Too thick or too thin, and your work might crack or look dull. Just as a good story needs the right rhythm, your glaze needs the right thickness. So, stay observant, trust your instincts, and let your surface tell you what it truly needs—like a whisper guiding your hands.