If you’re looking for the 13 best corrugated cardboard shredders for packaging in 2026, I’ve found several top options that stand out. These models handle waste efficiently, produce honeycomb mesh or strips, and are ideal for eco-friendly, cost-effective packaging solutions. They vary in size and power, with safety features and easy maintenance. Stay with me to discover which shredder best fits your needs and how to choose the right one.

Key Takeaways

- Highlights of top models with features like cutting width, thickness capacity, and shredding speed for efficient packaging.

- Emphasis on eco-friendly shredders capable of producing honeycomb mesh, strips, or void fill from waste cardboard.

- Safety features, ease of maintenance, and durability considerations for long-term industrial or small business use.

- Compatibility with various layers and sizes of corrugated cardboard for versatile packaging applications.

- Cost-effective options with support for continuous operation and sustainable waste reuse practices.

More Details on Our Top Picks

Recyclable Cardboard Shredder for Packaging and Boxes

If you’re looking for an eco-friendly and cost-effective way to handle waste cardboard, the Recyclable Cardboard Shredder is an excellent choice. It efficiently transforms irregular waste cardboard, unqualified boxes, and color boxes into eco-friendly packing fillers. With a powerful 1.5KW motor and a shredding speed of 9 meters per minute, it handles single-ply boxes up to 7mm thick. Its compact design, mobility wheels, and safety features make it user-friendly. By recycling old cardboard into protective fillers, it reduces packaging costs and minimizes waste, supporting environmental sustainability. This machine is perfect for businesses aiming to cut costs while being eco-conscious.

- Cutting Width:26 inches

- Maximum Thickness:7mm

- Power Source:220V

- Shredding Speed:9m/min

- Safety Features:Emergency stop, wheels with brakes

- Applications:Packaging filler production

- Additional Feature:Adjustable working direction

- Additional Feature:Emergency stop button

- Additional Feature:Four mobility wheels

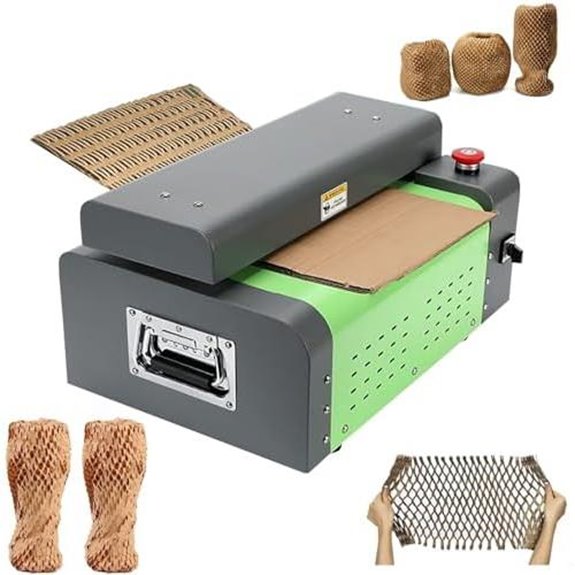

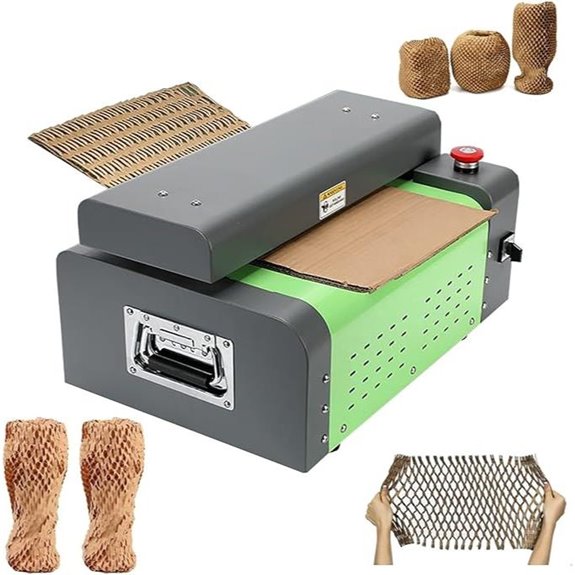

Cardboard Shredder for Packaging Waste Reuse

For packaging operations focused on sustainability and cost savings, a cardboard shredder designed for waste reuse offers an efficient solution. This machine features a 325mm feeding slot that handles material up to 6mm thick, running on standard 110V power with just 200W. Its compact design fits easily into most packing stations, optimizing space. The unique expansion cutting technology produces honeycomb-shaped mesh strips, providing excellent cushioning for fragile items like glassware and electronics. Built with heavy-duty components and safety features, including an emergency stop, it allows continuous operation. Reusing waste cardboard reduces material costs and supports eco-friendly packaging practices, making it an essential tool for sustainable warehouses.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V

- Shredding Speed:5m/min

- Safety Features:Emergency stop, stable base

- Applications:Cushioning/shipping protection

- Additional Feature:Honeycomb mesh output

- Additional Feature:Visible emergency stop

- Additional Feature:Compact space-saving design

Corrugated Box Expanding Cutter for Packing Material

The Corrugated Box Expanding Cutter stands out as an essential tool for small businesses and home users who need to transform large cardboard boxes into effective packing material quickly and efficiently. With advanced blades and precision cutting, it produces neat strips or tiny particles suited for protecting fragile items. Its cutting width of 325mm, shredding speed of 3m/min, and ability to handle up to 6mm thick material make it versatile for various packing needs. Designed with safety in mind, it features an ergonomic handle, one-button emergency stop, and easy maintenance. This machine helps reduce waste, organize space, and enhance packaging efficiency effortlessly.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, secure opening

- Applications:Packing material for fragile

- Additional Feature:Ergonomic portable handle

- Additional Feature:Tidy scrap cleaning area

- Additional Feature:Suitable for small businesses

Corrugated Box Expander and Cutter 325mm Width

This Corrugated Box Expander and Cutter with a 325mm width stands out as an ideal choice for small businesses and home users seeking efficient, versatile packaging solutions. It can handle cardboard up to 6mm thick and processes 3-5 layers of paper quickly at 3 meters per minute. With an ergonomic handle, adjustable speed, and safety features like an emergency stop, it offers both convenience and security. Its compact size and lightweight design make it easy to operate and maintain. Perfect for expanding and cutting large boxes into manageable strips, this machine streamlines packaging, especially for fragile items like ceramics, glasses, and artwork.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V/220V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, safety mechanisms

- Applications:Cushioning/shipping protection

- Additional Feature:Adjustable buffering speed

- Additional Feature:Dust collection system

- Additional Feature:Low noise operation

Recyclable Cardboard Shredder for Packaging (110V)

If you’re looking for an efficient way to recycle waste cardboard into packaging filler, the Recyclable Cardboard Shredder for Packaging (110V) is an excellent choice. It’s designed to transform old cardboard boxes into biodegradable, recyclable packing materials, ideal for fragile items like glass and ceramics. The machine operates with chain belts and gear transmission, shredding waste paper at about 5 meters per minute, with a maximum thickness of 10mm. Compact and user-friendly, it supports eco-friendly practices by converting waste into valuable packing filler, reducing packaging costs, and promoting environmental sustainability. Its versatility makes it perfect for processing mesh corrugated cardboard in logistics and packaging applications.

- Cutting Width:325mm

- Maximum Thickness:10mm

- Power Source:110V/220V

- Shredding Speed:5m/min

- Safety Features:Emergency stop, ergonomic handle

- Applications:Packaging filler, cushioning

- Additional Feature:Chain belt transmission

- Additional Feature:Reversible operation

- Additional Feature:Suitable for 3-5 layers

Corrugated Box Expansion Cutter and Shredder

For anyone seeking an efficient way to transform waste cardboard into versatile packaging material, the Corrugated Box Expansion Cutter and Shredder stands out. This machine converts cardboard into honeycomb mesh filler, perfect for cushioning fragile items like ceramics, electronics, or artwork. It features a 500mm cutting width, handles up to 10mm thick material, and shreds at 5 meters per minute. Using chain belts and gears, it offers quick, uniform mesh production with safety features like an emergency switch and ergonomic handle. Its durable design guarantees stable operation, low maintenance, and eco-friendly materials. Ideal for shipping, logistics, or creative packaging, it’s a versatile tool for sustainable packaging solutions.

- Cutting Width:500mm

- Maximum Thickness:10mm

- Power Source:110V/220V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, dust collection

- Applications:Packaging, creative design

- Additional Feature:Multiple color options

- Additional Feature:Automatic width adjustment

- Additional Feature:User-friendly tension control

Wasted Cardboard Slitting Mesh Cutter (500MM)

The Wasted Cardboard Slitting Mesh Cutter (500MM) stands out as an ideal choice for businesses seeking to convert waste cardboard into versatile packaging materials quickly and efficiently. It features a 500mm cutting width, handling up to 10mm thick material at a rate of 5 meters per minute. Perfect for 3-5 layers of waste paper, it transforms cardboard into honeycomb mesh filler through a precise 3D honeycomb cutting process. Using chain belts and gears, it guarantees smooth operation, with safety features like an emergency switch and ergonomic handle. This cutter helps reduce waste, create eco-friendly packaging, and supports sustainable practices across various industries.

- Cutting Width:500mm

- Maximum Thickness:10mm

- Power Source:110V/220V

- Shredding Speed:5m/min

- Safety Features:Emergency stop, ergonomic handle

- Applications:Cushioning, packaging

- Additional Feature:3D honeycomb cutting

- Additional Feature:Reversible blade rotation

- Additional Feature:Easy to organize waste

Corrugated Box Expansion Cutting Machine (500 MM)

A 500mm Corrugated Box Expansion Cutting Machine stands out as an ideal choice for businesses seeking to convert waste cardboard into versatile packaging material efficiently. It features a 3D honeycomb mesh shredder that transforms discarded cartons into useful filler, perfect for cushioning, wrapping, or creative projects. With a cutting width of 500mm and a maximum thickness of 10mm, it processes 3-5 layers of waste paper at a speed of 5m/min. Easy to operate and safe, it includes safety features like an emergency switch and ergonomic handle. This machine effectively reduces waste while producing high-quality packaging fillers for fragile items.

- Cutting Width:500mm

- Maximum Thickness:10mm

- Power Source:110V/220V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, safety features

- Applications:Packaging, cushioning

- Additional Feature:Energy-efficient operation

- Additional Feature:Suitable for creative uses

- Additional Feature:Quick blade replacement

Cardboard Shredder for Packaging Waste and Compost

If you manage high-volume packaging operations or prioritize sustainable practices, a cardboard shredder designed for waste and compost is an essential tool. It turns used boxes into free, effective void fill material, reducing packaging costs and waste. Capable of handling cardboard up to 325mm wide, it’s versatile for various box sizes. With a heavy-duty build and easy operation, it supports continuous shredding in busy settings like warehouses and shipping centers. Not only does it streamline your packaging process, but it also promotes eco-friendly practices by recycling waste into useful packing material, making it a smart investment for sustainable, cost-effective operations.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, safety cover

- Applications:Packaging, cushioning

- Additional Feature:Heavy-duty industrial build

- Additional Feature:Continuous operation design

- Additional Feature:Compatible with various waste sizes

Cardboard Shredder & Cutter for Eco Packaging

For small businesses and eco-conscious home users, a cardboard shredder and cutter that combines efficiency with safety is essential. This model features high-quality blades and smart cutting technology, transforming bulky cardboard into tidy strips or small pieces quickly. With a 325mm cutting width and optimized speed, it handles up to 6mm thick material, shredding 3-5 layers of paper effortlessly. Its ergonomic handle makes transport easy, while a secure rotating mechanism guarantees safe operation. Perfect for managing waste sustainably, it also processes honeycomb cardboard, making it ideal for eco-friendly packaging needs. Plus, the one-button emergency switch provides added safety during use.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V/220V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, ergonomic handle

- Applications:Eco packaging, waste reduction

- Additional Feature:Waste management features

- Additional Feature:Ergonomic handle

- Additional Feature:Hassle-free cleaning system

Cardboard Shredder for Waste and Packing Material

The Honeycomb Cardboard Box Cutting Machine stands out as an ideal choice for small businesses and home users who need to efficiently shred waste and packing materials. Its advanced blades and precise cutting mechanism quickly turn large boxes into neat strips or tiny particles. With a 325mm cutting width and a shredding speed of 3m/min, it handles up to 6mm thick material and 3-5 layers of paper, making it perfect for packing supplies. The ergonomic handle ensures portability, while the one-button emergency stop boosts safety. Easy to maintain with a dedicated scrap area, it keeps workspaces clean and supports eco-friendly waste management.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, secure access

- Applications:Packaging, waste reuse

- Additional Feature:Back paper scrap area

- Additional Feature:Versatile for small scale

- Additional Feature:User safety features

Corrugated Cardboard Expansion Cutter 300cm/min 325mm

The Corrugated Cardboard Expansion Cutter with a 300cm/min shredding speed and 325mm cutting width stands out as an ideal choice for packaging operations that demand quick and efficient processing of bulky boxes. It transforms cardboard into usable packing material by disassembling large boxes into strips or particles, helping reduce waste and improve resource utilization. With advanced blades and mechanisms, it handles waste paper up to 6mm thick, making it versatile for various materials like cardboard, paper, and layered waste. Its ergonomic design, safety features, and simple operation make it user-friendly, ensuring fast, safe, and cost-effective packaging solutions.

- Cutting Width:325mm

- Maximum Thickness:6mm

- Power Source:110V/220V

- Shredding Speed:3m/min

- Safety Features:Emergency stop, safety mechanisms

- Applications:Packaging, creative uses

- Additional Feature:High resource efficiency

- Additional Feature:Multiple waste type support

- Additional Feature:Reusable packaging material

Recyclable Cardboard Shredder for Packaging (110V)

If you’re seeking an eco-friendly solution to turn packaging waste into useful materials, the Recyclable Cardboard Shredder for Packaging (110V) stands out as a practical choice. This machine efficiently converts old cardboard boxes into biodegradable packing fillers, helping reduce costs and support sustainability. It’s perfect for shredding mesh corrugated cardboard used in packaging fragile items like electronics, ceramics, and glass. Operating via chain belts and gear transmission, it handles waste paper up to 10mm thick at a speed of 5 meters per minute. Compact and lightweight, it’s ideal for small to medium businesses aiming to recycle waste while promoting eco-conscious practices.

- Cutting Width:350mm

- Maximum Thickness:10mm

- Power Source:110V/220V

- Shredding Speed:5m/min

- Safety Features:Emergency stop, safety features

- Applications:Waste recycling, packaging

- Additional Feature:Suitable for fragile items

- Additional Feature:Eco-friendly decomposable material

- Additional Feature:Reversible operation mode

Factors to Consider When Choosing a Corrugated Cardboard Shredder for Packaging

When selecting a corrugated cardboard shredder, I consider factors like capacity to handle my workload and compatibility with the materials I use. I also look at power efficiency, safety features, and whether the size and portability fit my workspace. These points help make certain I choose a shredder that meets my packaging needs effectively.

Shredder Capacity Needs

Choosing the right corrugated cardboard shredder depends heavily on understanding your capacity needs. First, consider the maximum width your shredder can handle, usually between 300mm and 500mm, to match your packaging waste size. Next, check the maximum thickness capacity, typically 6mm to 10mm, guaranteeing it can process your thickest materials. Shredder speed is also vital; speeds from 3m/min to 9m/min help determine if it can keep up with your production volume. Additionally, match the capacity in layers of paper, often 3-5 layers, to your daily waste generation to avoid jams. Lastly, guarantee the shredder’s workload aligns with your expected usage to prevent frequent overloads or disruptions during operation.

Material Compatibility Types

Selecting a corrugated cardboard shredder requires guaranteeing it can handle the specific types and qualities of materials you’ll process. First, check that it supports the maximum thickness you need, typically up to 6-10mm for corrugated sheets. It should also handle multiple layers, usually 3-5, for efficient cutting. Compatibility with various cardboard types—single-ply, double-ply, or multi-layer—is essential for versatility. Additionally, guarantee it can process different waste papers such as kraft, scrap, or colored boxes, broadening your recycling options. If you work with specialized materials like honeycomb or mesh cardboard for packaging fillers, verify that the shredder can handle these as well. Matching your shredder’s capabilities with your material types ensures smooth operation and maximum results.

Power and Efficiency

Power and efficiency play a significant role in guaranteeing your corrugated cardboard shredder keeps up with your packaging demands. A higher shredding speed, around 3-9 meters per minute, boosts productivity and cuts down processing time. Machines with greater cutting capacity and maximum thickness, like 6-10mm, can handle more waste in a single pass, making operations smoother. Power consumption, typically between 200W and 1.5KW, affects operational costs and speed; more power usually means faster shredding. Advanced blades and mechanisms, such as chain belts and gear systems, improve cutting precision and speed. Reliable motor performance assures steady operation, reducing downtime and maximizing throughput during continuous use. Prioritizing power and efficiency helps you choose a shredder that keeps pace with your packaging needs.

Safety Features Included

Safety features are essential when evaluating corrugated cardboard shredders because they directly impact user protection and operational risks. Emergency stop buttons provide immediate shutdowns if something goes wrong, preventing injuries. Safety guards and covers on moving blades help keep hands away from danger, reducing the chance of cuts or worse. The reverse function is a handy feature that allows quick jam clearing without manual blade handling, minimizing exposure to moving parts. Non-slip bases or locking mechanisms ensure the shredder stays stable during operation, preventing accidents caused by shifting. Automatic shut-off systems detect unsafe conditions and turn the machine off instantly, adding an extra layer of safety. These features work together to create a safer working environment and give users peace of mind during operation.

Size and Portability

When choosing a corrugated cardboard shredder, size and portability are crucial factors to take into account because they directly affect how well the machine fits into your workspace and how easily you can move it when needed. I recommend considering the shredder’s dimensions and weight to guarantee it comfortably fits your area and remains manageable for your team. Look for models with wheels or handles that make repositioning simple, especially if your workspace changes frequently. Check the maximum width and height capacity to confirm it can handle your typical cardboard sizes. A compact design can save space without sacrificing performance. Finally, ensure the weight is manageable so your team can safely set up, maintain, or move the shredder when necessary.

Environmental Impact

Considering the environmental impact of corrugated cardboard shredders is vital when selecting the right machine for your packaging needs. I look for shredders that recycle waste into biodegradable packing materials, which helps reduce landfill waste and pollution. Energy-efficient motors are also essential, as they lower the carbon footprint during operation. I prefer machines that produce eco-friendly fillers, supporting sustainable packaging and decreasing reliance on non-recyclable materials. Handling various thicknesses and layers ensures maximum reuse of waste cardboard, conserving resources. Additionally, shredders with safety features and responsible disposal mechanisms prevent environmental hazards and promote eco-conscious practices. By choosing shredders with these considerations, I can minimize environmental impact while maintaining effective packaging solutions.

Cost and Maintenance

Choosing a corrugated cardboard shredder requires careful attention to both upfront costs and ongoing expenses. I recommend comparing the initial purchase price with long-term costs like replacement parts and consumables, which can add up over time. Maintenance needs are vital—frequently sharpened or replaced blades can cause downtime and increase costs. Look for models with features that simplify upkeep, such as easy-access blades or self-cleaning options, saving labor and repair expenses. Durability matters too; a well-built shredder with quality materials will last longer, reducing the need for frequent replacements. Don’t forget to review warranty options and after-sales support, as they can considerably lower repair and maintenance costs throughout the machine’s lifespan. Balancing these factors helps guarantee cost-effective, reliable operation.

Frequently Asked Questions

What Safety Features Are Essential in Corrugated Cardboard Shredders?

Safety features are vital when using corrugated cardboard shredders. I always look for emergency stop buttons, safety guards, and automatic shut-off systems to prevent accidents. Clear safety instructions and interlock mechanisms ensure I can operate the machine confidently without risking injury. Regular maintenance and safety training are essential too. These features give me peace of mind, knowing I can work efficiently while staying safe.

How Does Shredder Maintenance Impact Long-Term Efficiency?

Think of shredder maintenance like tending a garden; neglecting it leads to weeds and chaos. I’ve seen firsthand how regular cleaning and oiling keep shredders running smoothly, preventing breakdowns and costly repairs. Consistent upkeep ensures peak performance and extends the machine’s lifespan. Skipping maintenance might save time initially, but it ultimately hampers efficiency and increases downtime. Proper care is key to long-term shredding success.

Can Shredders Handle Mixed or Contaminated Cardboard Waste?

Yes, shredders can handle mixed or contaminated cardboard waste, but it depends on the machine’s specifications. I’ve found that heavy-duty shredders with robust blades and powerful motors are best suited for this task. However, I always recommend removing excessive contaminants like plastic or metal to prevent damage. Properly maintaining your shredder also guarantees consistent performance and longevity, especially when processing varied and potentially dirty materials.

What Are the Environmental Benefits of Using Eco-Friendly Shredders?

Using eco-friendly shredders is like giving nature a new lease on life. They greatly reduce energy consumption and emissions compared to traditional models, helping fight pollution. Plus, they promote recycling by efficiently processing cardboard waste into reusable materials. I’ve seen how switching to green shredders not only benefits the environment but also boosts our company’s sustainability image. It’s a smart move for both planet and business.

How Does Shredding Speed Affect Packaging Workflow Productivity?

Shredding speed directly impacts packaging workflow productivity by determining how quickly I can process materials. Faster shredders allow me to keep up with high-volume demands, reducing bottlenecks and downtime. However, I also consider quality; if speed jeopardizes the shredded material’s usability, it can slow down overall efficiency. Striking the right balance ensures I maximize throughput without sacrificing the quality needed for effective packaging.

Conclusion

Choosing the right corrugated cardboard shredder is like finding the perfect tool to breathe new life into waste, transforming cluttered boxes into useful packing material. Imagine your workspace clutter-free, with shredded cardboard neatly ready to cushion fragile items. With these top shredders, you’ll turn waste into a sustainable resource effortlessly. So, pick one that fits your needs, and watch your packaging process become more efficient, eco-friendly, and satisfying—making every shred count.