If you’re looking for the best induction heaters for jewelry annealing in 2026, I recommend considering options with varying power capacities like a 15KW high-frequency unit for industrial needs or smaller models like a 120W heater for hobbyist projects. Features such as precise temperature control, safety safeguards, and material compatibility are essential. Keep in mind portability and cost, and if you continue exploring, you’ll find detailed insights to help you choose the perfect heater for your jewelry work.

Key Takeaways

- The top induction heaters for jewelry annealing in 2026 offer versatile power options from 120W to 15KW for various scales.

- Precise temperature control features, including digital displays and real-time monitoring, ensure high-quality results.

- Compatibility with multiple metals and alloys, with uniform heating, minimizes damage and enhances process efficiency.

- Safety features like overload protection, automatic shutdown, and cooling systems guarantee reliable operation.

- Compact, user-friendly designs with adjustable settings and affordability make these heaters ideal for hobbyists and professionals.

| 15KW High Frequency Induction Heater for Metalworking |  | Professional Power | Power Range: 15KW | Input Voltage: 220V (implied for industrial) | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

| Induction Heating Module 12-48V 1000W DIY Heater |  | DIY Essential | Power Range: 1000W | Input Voltage: 12-48V DC | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

| High-Frequency Induction Heating Machine with Digital Display |  | Precision Control | Power Range: 3000W | Input Voltage: Not specified (industrial-grade) | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

| ZVS Low Voltage Induction Heating Board Module Flyback Driver Heater |  | Educational Tool | Power Range: Not specified (flyback driver) | Input Voltage: Not specified (depends on external power supply) | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

| 120W Induction Heater for Jewelry Making and Metal Casting |  | Compact Efficiency | Power Range: 120W | Input Voltage: 5V-12V DC | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

| Magnetic Copper Heater 1500W Adjustable Flameless Water-Cooled |  | Heavy-Duty Remover | Power Range: 1500W | Input Voltage: 110/220/240V | Heating Method: Induction | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

15KW High Frequency Induction Heater for Metalworking

If you’re looking for a reliable solution for metalworking, the 15KW High Frequency Induction Heater stands out thanks to its advanced MOSFET and IGBT power units, which deliver precise and consistent heat. Its durable stainless steel shell guarantees it can operate continuously for 24 hours, making it ideal for industrial use. With a maximum temperature of 2200℃, it supports melting, welding, and annealing processes across various metals. The integrated water cooling system enhances safety and longevity, while adjustable settings allow for accurate control of heating times and power output. This versatile, high-performance heater boosts efficiency and reliability in demanding metalworking applications.

- Power Range:15KW

- Input Voltage:220V (implied for industrial)

- Heating Method:Induction

- Control Type:Digital controls, adjustable parameters

- Cooling System:Water cooling

- Application Scope:Metal melting, welding, annealing

- Additional Feature:Max temperature 2200℃

- Additional Feature:Infrared temperature detector (optional)

- Additional Feature:Continuous 24-hour operation

Induction Heating Module 12-48V 1000W DIY Heater

The Induction Heating Module 12-48V 1000W DIY Heater is ideal for jewelry makers seeking a compact, efficient solution for annealing and small-scale metalworking. Its low-voltage ZVS flyback driver delivers up to 1000W of power, supporting voltages from 12V to 48V. Designed for DIY projects, it heats small parts evenly and quickly, making it perfect for melting gold, silver, copper, and aluminum with a graphite crucible. The coil, with a 40mm diameter and 50mm height, suits moderate power applications. Easy to operate and reliable, it’s a versatile tool for precise heat treatment, hardening, and annealing in jewelry crafting.

- Power Range:1000W

- Input Voltage:12-48V DC

- Heating Method:Induction

- Control Type:DIY, manual operation

- Cooling System:No cooling fan (air-cooled)

- Application Scope:Small parts heating, diy metal melting

- Additional Feature:Suitable for small parts

- Additional Feature:Uniform heating response

- Additional Feature:Supports DIY applications

High-Frequency Induction Heating Machine with Digital Display

A high-frequency induction heating machine with a digital display stands out as an ideal choice for jewelry artisans and small-scale metalworkers who demand precise control and reliable performance. With up to 3000W of power, it provides quick, uniform, flameless heat perfect for melting, forging, casting, and heat treating small metal parts. Compatible with gold, silver, copper, and aluminum, it offers versatility for various projects. Its digital controls allow accurate temperature, speed, and time adjustments, with manual and automatic modes for consistent results. Compact and durable, it features built-in safety protections and a water cooling system, making it a dependable tool for professional or hobbyist use.

- Power Range:3000W

- Input Voltage:Not specified (industrial-grade)

- Heating Method:Induction

- Control Type:Digital display, precise control

- Cooling System:Water cooling system

- Application Scope:Melting, forging, jewelry, lab work

- Additional Feature:Digital temperature control

- Additional Feature:Portable and rugged design

- Additional Feature:Supports scientific research

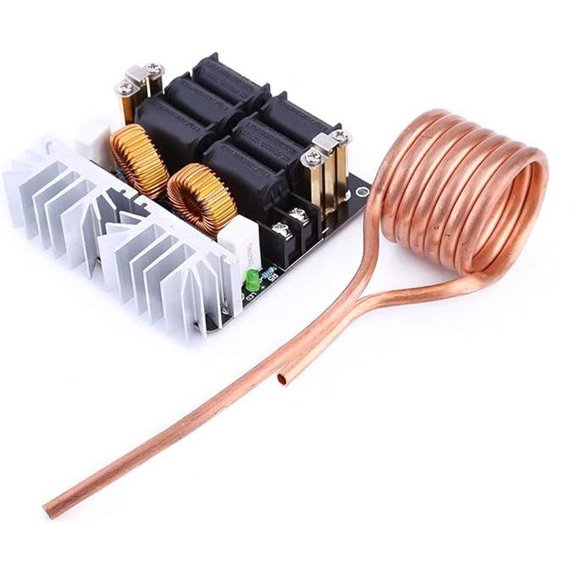

ZVS Low Voltage Induction Heating Board Module Flyback Driver Heater

Designed specifically for students and practical learners, the ZVS Low Voltage Induction Heating Board Module Flyback Driver Heater offers a straightforward setup that enhances hands-on skills in jewelry annealing. Its durable, wear-resistant materials ensure longevity in educational environments. Easy to operate, it includes a heating coil and requires proper circuit setup for peak performance. You must verify correct wiring and use a sufficiently rated power supply, as it’s not compatible with batteries or portable sources. Following proper assembly and safety precautions prevents damage and ensures reliable operation. This module is an excellent choice for developing practical understanding and experience in induction heating techniques for jewelry.

- Power Range:Not specified (flyback driver)

- Input Voltage:Not specified (depends on external power supply)

- Heating Method:Induction

- Control Type:Simple operation, setup required

- Cooling System:Not specified (depends on power supply)

- Application Scope:DIY projects, small metal parts

- Additional Feature:Protective power supply included

- Additional Feature:Easy to operate

- Additional Feature:Suitable for educational use

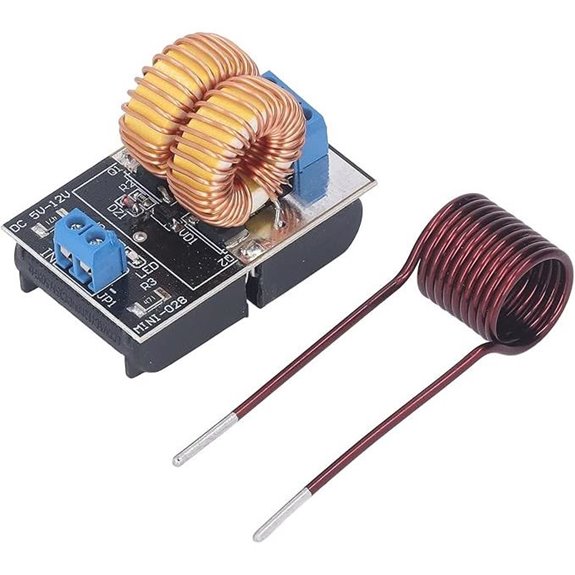

120W Induction Heater for Jewelry Making and Metal Casting

If you’re looking for a reliable and efficient tool for jewelry making and small-scale metal casting, a 120W induction heater is an excellent choice. It delivers fast, uniform heating thanks to its DC 5V-12V input, melting gold, silver, copper, and aluminum with ease. Its user-friendly design features no ignition coil or cooling fan, making it compact and easy to operate. The built-in ZVS driver module ensures safe, consistent performance by regulating voltage and preventing overheating. Compatible with graphite crucibles (sold separately), this versatile device is perfect for jewelry creation, repairs, and casting projects, combining simplicity with reliable power.

- Power Range:120W

- Input Voltage:5V-12V DC

- Heating Method:Induction

- Control Type:User-friendly, straightforward operation

- Cooling System:No cooling (compact design)

- Application Scope:Jewelry making, small casting, repairs

- Additional Feature:No ignition coil needed

- Additional Feature:Compact, space-saving design

- Additional Feature:Safe for extended use

Magnetic Copper Heater 1500W Adjustable Flameless Water-Cooled

The Magnetic Copper Heater, 1500W, is perfect for professionals who require precise, flameless heating in their jewelry annealing or metal repair tasks. Its rapid induction heating efficiently targets bolts, bearings, shafts, and copper or steel workpieces, making it versatile for various applications. The built-in 2.5L water cooling tank, combined with air cooling, eliminates the need for external water sources, ideal for outdoor or remote use. Its adjustable power via an LED screen ensures control over heating intensity. Compact and portable at 15kg, it’s designed for strength, safety, and ease of operation, supporting both delicate jewelry work and heavy-duty repairs.

- Power Range:1500W

- Input Voltage:110/220/240V

- Heating Method:Induction

- Control Type:Digital display, adjustable settings

- Cooling System:Water cooling system

- Application Scope:Repair, bolt removal, annealing

- Additional Feature:Built-in water cooling tank

- Additional Feature:Automatic safety shutdowns

- Additional Feature:Extended cable length (up to 200m)

Factors to Consider When Choosing an Induction Heater for Jewelry Annealing

When selecting an induction heater for jewelry annealing, I consider several key factors to guarantee it meets my needs. These include power capacity, temperature control accuracy, and compatibility with different materials. Safety features and ease of use also play a vital role in making the right choice.

Power Capacity Needs

How do you determine the right power capacity for your jewelry annealing needs? First, consider the size and type of jewelry you work with. Smaller pieces often require less power—around 120W to 300W—since they heat quickly and need precise control. Larger or denser metal items, on the other hand, benefit from higher wattage units, such as 3000W or more, which enable faster, more efficient heating. If you’re handling a variety of projects, an induction heater with adjustable power output offers flexibility, allowing you to match the wattage to each task. Remember, choosing a power capacity that aligns with your specific annealing process guarantees ideal results without wasting energy or risking damage to delicate pieces.

Temperature Precision Control

Choosing an induction heater with precise temperature control is essential for achieving consistent jewelry annealing results. Accurate control helps prevent overheating or underheating, ensuring the metal reaches the desired properties without damage. Look for models with adjustable heating times, typically from 1 to 99 seconds, to fine-tune temperature levels during the process. Infrared temperature detectors or built-in thermometers are invaluable for automatic regulation and real-time monitoring of the metal’s temperature. Frequency conversion control further stabilizes temperature output, providing uniform heating across the jewelry piece. This level of precision not only safeguards delicate components but also guarantees consistent, high-quality results. Investing in an induction heater with advanced temperature control features makes your annealing process more reliable and efficient.

Material Compatibility Range

Selecting an induction heater that supports a broad material compatibility range guarantees you can work with various metals like gold, silver, copper, and aluminum. This flexibility is essential for handling different jewelry projects and alloy compositions. Make sure the heater can reach temperatures up to 2200°C, which is necessary for effectively annealing diverse materials. Adjustable power levels and heating times are also critical for precise control, allowing you to tailor the process to each piece. Uniform heating is equally important to prevent uneven annealing or damage to delicate, intricate jewelry items. Additionally, check if the device offers multi-metal compatibility, ensuring it can manage various alloys used in jewelry making. These features help optimize your workflow and improve the quality of your finished pieces.

Safety and Overload Protection

Have you considered the significance of safety features when picking an induction heater for jewelry annealing? Safety protections are essential to prevent damage and ensure user safety. I look for models with built-in overload protection to guard against electrical surges and excessive current, which can harm the device. Over-voltage, over-current, and overheating safeguards are critical to maintain safe operation and prevent accidents. Additionally, automatic shutdown features are essential—they kick in if there’s a water shortage or phase failure, stopping potential hazards before they escalate. I also check for status indicators or alarms that alert me to electrical issues during use. A reliable cooling system, such as water cooling or high-temperature safety cutoffs, further guarantees the heater operates safely, keeping both the device and user protected.

Ease of Operation

Ease of operation is essential when using an induction heater for jewelry annealing, especially if you want consistent results without hassle. Intuitive digital controls make it simple to set precise temperatures and heating durations, which is great for both beginners and seasoned jewelers. Adjustable power levels and pre-programmed cycles help streamline tasks, reducing manual adjustments and saving time. Features like automatic temperature regulation and clear, easy-to-read displays ensure consistent outcomes without needing complex knowledge. Compact, portable designs with minimal setup make it quick to deploy in various environments. Additionally, user-friendly interfaces and safety indicators minimize operational errors, making the process safer and more manageable. Overall, an induction heater that prioritizes ease of operation ensures a smoother, more efficient annealing experience.

Size and Portability

When choosing an induction heater for jewelry annealing, size and portability play a significant role in making sure it fits seamlessly into your workspace or on-the-go setup. Compact models with smaller footprints are ideal, as they save space and make handling easier. Lightweight designs and built-in handles enhance portability, allowing you to move the unit effortlessly between workstations or locations. Devices with integrated cooling systems eliminate the need for external water sources, which is especially beneficial for field or on-site work. Smaller heaters typically operate at lower wattages, such as 120W to 3000W, providing precise control without bulk. Additionally, consider the size of the heating coil and overall dimensions to ensure compatibility with jewelry pieces and ease of operation in tight or limited spaces.

Cooling System Effectiveness

How well an induction heater manages its cooling system directly affects its performance and durability during jewelry annealing. An effective cooling system prevents overheating of internal components, ensuring safe and reliable operation during extended use. Water cooling is common, and the flow rate and heat exchange capacity are key factors that influence efficiency. Automatic temperature regulation features help maintain stable temperatures, reducing thermal stress and protecting components from damage. A high-quality cooling system not only improves performance but also extends the heater’s lifespan by minimizing thermal degradation. Proper insulation and water circulation design are essential for maximum cooling efficiency, ensuring uniform temperature control throughout the annealing process. In short, a robust cooling system is essential for consistent, safe, and long-lasting operation.

Price and Budget Fit

Choosing an induction heater for jewelry annealing involves more than just its cooling system; your budget plays a significant role in the decision. It’s crucial to verify the heater’s price fits within your overall jewelry-making budget. Consider whether the cost reflects the heater’s power capacity and features necessary for effective annealing. Higher-priced models typically offer better temperature control and safety features, which can improve results and safety. Balancing initial investment with long-term operational costs is also essential—more energy-efficient and durable models can save money over time. Don’t overlook affordable options that deliver fundamental functionalities without sacrificing quality or safety. Finding a heater that meets your needs while staying within your budget helps you make a smart, sustainable investment in your jewelry-making process.

Frequently Asked Questions

What Safety Features Are Most Important in Jewelry Annealing Induction Heaters?

The most important safety features in jewelry annealing induction heaters are automatic shut-off, thermal overload protection, and adequate insulation. These features prevent overheating, protect against electrical faults, and guarantee safe handling. I always look for units with clear safety indicators and easy-to-access emergency stop buttons. Prioritizing these safety features helps me work confidently, knowing that both my safety and my jewelry are protected during the annealing process.

How Does Coil Design Impact Heating Efficiency for Jewelry Annealing?

Coil design directly impacts heating efficiency by focusing magnetic fields, enhancing power transfer, and ensuring even heat distribution. I find that a well-shaped coil with proper turns and spacing enhances energy concentration at the jewelry piece, reducing energy waste and heating time. Conversely, poorly designed coils can cause uneven heating and inefficiency. So, I always pay close attention to coil geometry for ideal results in jewelry annealing.

Can Portable Induction Heaters Handle Continuous Jewelry Annealing Tasks?

Yes, portable induction heaters can handle continuous jewelry annealing tasks, but it depends on their power and build quality. I’ve used some models that work well for small batches, yet for larger or nonstop work, I recommend heavy-duty units with higher wattages and robust cooling systems. Always check the specifications to guarantee it matches your workload, as not all portable options are designed for continuous use.

What Maintenance Is Required to Ensure Long-Term Performance of Induction Heaters?

Think of your induction heater like a finely tuned engine—it needs regular care to run smoothly. I recommend cleaning the coil and venting periodically to prevent dust buildup, inspecting cables and connections for wear, and checking calibration to keep performance sharp. Keep the unit dry and store it properly when not in use. Performing these simple maintenance steps guarantees your heater stays reliable and efficient for years to come.

Are There Environmentally Friendly or Energy-Efficient Induction Heater Options?

Yes, there are environmentally friendly and energy-efficient induction heater options available. I recommend looking for models with high energy efficiency ratings, such as those with advanced power control features that minimize energy waste. Many newer units use eco-friendly materials and are designed to reduce electromagnetic emissions. By choosing these, you not only save energy but also reduce your environmental impact, making your jewelry annealing process more sustainable.

Conclusion

Choosing the right induction heater is like finding the perfect key to *unseal* your jewelry’s true brilliance. Each option offers a different rhythm—some fast and powerful, others precise and gentle. By understanding what your projects need, you’ll strike the right chord in your craftsmanship. Remember, the right heater doesn’t just heat metal; it ignites your creativity, turning raw material into stunning jewelry. Trust your instincts and make that perfect connection today.