If you’re searching for the 15 best tabletop kilns for small ceramics in 2026, I’ve got you covered. These models include precise, digital-controlled kilns perfect for jewelry, small sculptures, and metal projects. They feature advanced heating systems, safety features, and durable construction, all designed for consistent results. Whether you’re a hobbyist or a professional, these options offer reliable performance. Keep exploring to find the best fit for your needs and projects.

Key Takeaways

- Top tabletop kilns in 2026 feature precise digital controls and high-temperature capabilities up to 2200°F for small ceramics.

- They are designed with durable, high-temp materials and safety features for reliable, long-term use.

- Compact sizes (e.g., 15x15x20 cm) make these kilns ideal for small studios, hobbyists, and jewelry making.

- Many models support rapid heating, programmable firing cycles, and versatile applications like glass fusing and metal melting.

- Certified quality and safety, including overheat protection and American-made options, ensure dependable performance for small ceramic projects.

| Pro Tabletop Kiln for Pottery & Jewelry Making |  | Best Overall | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| Tabletop Kiln for Jewelry Dental Hobby Use |  | Versatile Choice | Max Temperature: 800°C | Power Rating: 1500W | Chamber Dimensions: 15×15×20 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| Compact Electric Kiln with Temperature Control |  | Compact & Reliable | Max Temperature: 1000°C | Power Rating: Not specified (but likely around 1500W) | Chamber Dimensions: 195×170 mm (≈19.5×17 cm) | VIEW LATEST PRICE | See Our Full Breakdown |

| 2000W Electric Kiln with Accessories and Tongs |  | High-Temperature Performance | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| High-Temp Burnout Furnace 2102℉ (1150℃) 2000W |  | Professional Grade | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| Burnout Kiln & Lab Oven 1150°C with Accessories |  | User-Friendly Design | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| TableTop USA Programmable Electric Burnout Furnace |  | Space-Saving Power | Max Temperature: 2200°F (~1200°C) | Power Rating: Not specified | Chamber Dimensions: 3 x 5 flasks (size not specified, but designed for small molds) | VIEW LATEST PRICE | See Our Full Breakdown |

| Tabletop Electric Kiln Kit for Jewelry and Ceramics |  | Multi-Purpose Use | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| 195x170mm Microwave Kiln for Firing Ceramics and Fused Glass Up to 1200 ℃ |  | Easy Operation | Max Temperature: 1200°C | Power Rating: Not specified | Chamber Dimensions: φ130 x H90 mm | VIEW LATEST PRICE | See Our Full Breakdown |

| Electric Burnout Oven Kiln for Ceramic & Jewelry Making |  | Heavy-Duty Construction | Max Temperature: 1150°C | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| Pro Tabletop Kiln for Pottery & Jewelry Making |  | Ideal for Small Spaces | Max Temperature: 1150°C | Power Rating: Not specified | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| 195x170mm Microwave Kiln for Firing Ceramics and Fused Glass Up to 1200 ℃ |  | Fast Heating | Max Temperature: 1200°C | Power Rating: Not specified | Chamber Dimensions: φ75 x H90 mm | VIEW LATEST PRICE | See Our Full Breakdown |

| VEVOR 1500W Electric Kiln for Metal & Clay |  | Budget-Friendly | Max Temperature: 1200°C | Power Rating: 1500W | Chamber Dimensions: Larger chamber, specifics vary | VIEW LATEST PRICE | See Our Full Breakdown |

| Weysat Kiln Shelf for Glass Fusing and Ceramics |  | High-Performance Model | Max Temperature: 2280°F (~1249°C) | Power Rating: 2000W | Chamber Dimensions: 16×16×13.8 cm | VIEW LATEST PRICE | See Our Full Breakdown |

| Verdanzia 2 Pack 7″ Square Kiln Shelves |  | Durable & Efficient | Max Temperature: 2280°F (~1249°C) | Power Rating: Not specified (but likely 2000W based on similar models) | Chamber Dimensions: 7×7 inches (≈18×18 cm) | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Pro Tabletop Kiln for Pottery & Jewelry Making

The Pro Tabletop Kiln is ideal for professional jewelers and small-scale ceramic artists because it offers precise temperature control and uniform heat distribution. I appreciate its advanced four-sided surround heating and intelligent regulation, which guarantee consistent results whether I’m melting metals or firing pottery. The digital display and high-precision sensors allow me to monitor and adjust temperatures in real-time, preventing overheating. Its spacious interior fits multiple molds at once, making batch work efficient. Built with durable, high-temperature materials and reinforced insulation, this kiln is reliable, safe, and energy-efficient—perfect for small studios or home workshops seeking professional-grade performance.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital display, intelligent regulation

- Material/Construction:High-temp resistant materials, reinforced lining

- Additional Feature:Spacious internal cavity (16×16×13.8 cm)

- Additional Feature:Sealed door with insulation

- Additional Feature:Supports batch processing

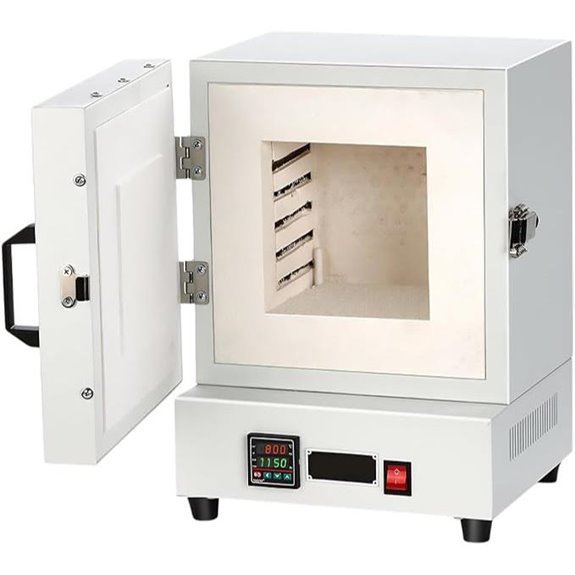

Tabletop Kiln for Jewelry Dental Hobby Use

If you’re a jewelry maker, dental technician, or hobbyist, this tabletop kiln is an essential tool that combines precise temperature regulation with quick, even heating. It reaches 800°C in just 30-40 minutes thanks to advanced four-sided heating technology, which ensures uniform heat distribution. The intuitive PID digital controller offers accurate temperature regulation within ±1°C, making it perfect for metal clay sintering, enamel firing, and alloy melting. Built with durable, insulated materials and a cool-to-touch exterior, it’s safe and long-lasting. Its spacious chamber (15x15x20 cm) supports batch processing of multiple molds or larger pieces, making it versatile for various small-scale projects.

- Max Temperature:800°C

- Power Rating:1500W

- Chamber Dimensions:15×15×20 cm

- Heating Technology:Four-sided surround heating

- Control System:PID digital controller

- Material/Construction:Refractory materials, stainless shell

- Additional Feature:Interior chamber 15x15x20 cm

- Additional Feature:Cool-to-touch exterior

- Additional Feature:Versatile for multiple crafts

Compact Electric Kiln with Temperature Control

A compact electric kiln with a digital temperature controller is an excellent choice for hobbyists and professionals who need precise, reliable firing in limited space. It’s lightweight, space-efficient, and features a quartz window, safety switch, and two ceramic shelves. Capable of reaching 1000°C (1832°F), it’s perfect for working with small wood, metal, stones, PMC, clay, waxes, and enamels. Professionally packed for worldwide shipping, it guarantees consistent results without issues common to fake kilns. Plus, its digital control ensures accurate temperature management, making it ideal for those seeking dependable performance and versatile firing options in a small, table-top design.

- Max Temperature:1000°C

- Power Rating:Not specified (but likely around 1500W)

- Chamber Dimensions:195×170 mm (≈19.5×17 cm)

- Heating Technology:Quartz chamber with heating elements

- Control System:Digital temperature controller

- Material/Construction:Ceramic fiber lining, durable shell

- Additional Feature:Quartz viewing window

- Additional Feature:Professionally packed shipping

- Additional Feature:Digital user manual available

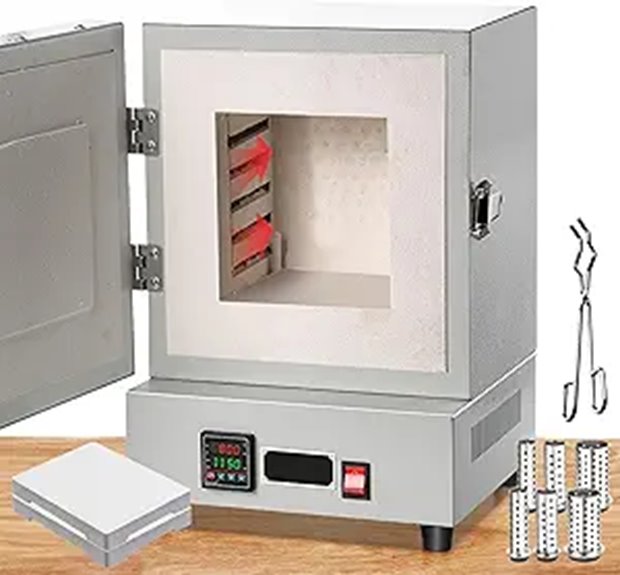

2000W Electric Kiln with Accessories and Tongs

Designed for hobbyists and small-scale professionals, the 2000W Electric Kiln with Accessories and Tongs offers rapid, even heating thanks to its four-sided surround technology. It heats up quickly and evenly, reaching 1150°C for high-temperature projects like burnout, sintering, or metal melting. Built with durable, high-temperature resistant materials, it’s designed for long-lasting performance. The kiln features an intuitive digital display for precise temperature control from 0-1150°C. Its compact interior (16x16x13.8cm) accommodates multiple molds or small batches. Plus, it comes with useful accessories like ceramic shelves, flasks, and tongs, making it versatile for a variety of crafts.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital display, precise adjustment

- Material/Construction:High-temp resistant materials, reinforced lining

- Additional Feature:Includes casting flasks

- Additional Feature:16×16×13.8 cm interior

- Additional Feature:Supports high-temp applications

High-Temp Burnout Furnace 2102℉ (1150℃) 2000W

The High-Temp Burnout Furnace 2102℉ (1150℃) 2000W stands out as an excellent choice for professionals and serious hobbyists who need reliable, high-temperature performance for casting and metalworking. Its durable construction features high-temperature, corrosion-resistant materials, reinforced heating coils, and a spacious chamber (16×16×13.8cm) that handles multiple molds. With advanced four-sided surround heating, it ensures even heat distribution, while the digital interface offers precise temperature control from 0 to 1150℃. Perfect for jewelry, wax burnout, and metal melting, this furnace delivers consistent results and extended durability for demanding applications.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital control, temperature regulation

- Material/Construction:High-temp resistant, durable materials

- Additional Feature:Thickened furnace wire

- Additional Feature:Large chamber for molds

- Additional Feature:Reinforced heating coil

Burnout Kiln & Lab Oven 1150°C with Accessories

If you’re looking for a versatile kiln that handles high-temperature applications with precision, the Burnout Kiln & Lab Oven 1150°C with Accessories is an excellent choice. It features four-sided surround heating for rapid, even heat distribution, preventing hot spots. Capable of reaching 1150°C, it’s perfect for metal melting, ceramic firing, and burnout tasks. Its digital display allows precise temperature control from 0-1150°C, ensuring consistent results. The compact design offers a spacious interior (16x16x13.8cm), ideal for small projects and batch processing. Plus, it comes with essential accessories like casting flasks, ceramic shelves, and tongs, making it a reliable studio tool for various crafts.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital display, PID control

- Material/Construction:High-temp resistant, reinforced materials

- Additional Feature:Includes ceramic shelves and tongs

- Additional Feature:Compact tabletop design

- Additional Feature:Ventilation holes for cooling

TableTop USA Programmable Electric Burnout Furnace

For those seeking precise control in small-scale burnout applications, the TableTop USA Programmable Electric Burnout Furnace stands out with its advanced programmable controller and high-temperature capabilities. It reaches up to 2200°F, making it perfect for jewelry, dental casting, wax burnout, and 3D resin or PLA projects. The furnace’s pre-drilled vent and high-temperature thermocouple guarantee accurate temperature regulation and safety. Its compact size fits 3 x 5 flasks or smaller, ideal for both hobbyists and professionals. Made in the USA, this furnace offers reliable, efficient performance for various burnout processes, combining durability with easy programmability.

- Max Temperature:2200°F (~1200°C)

- Power Rating:Not specified

- Chamber Dimensions:3 x 5 flasks (size not specified, but designed for small molds)

- Heating Technology:Not specified, but programmable with temperature control

- Control System:Programmable controller

- Material/Construction:Metal exterior, ceramic chamber

- Additional Feature:Made in the U.S.A.

- Additional Feature:Pre-drilled vent hole

- Additional Feature:Supports 3 x 5 flasks

Tabletop Electric Kiln Kit for Jewelry and Ceramics

A tabletop electric kiln kit designed for jewelry and ceramics stands out for its rapid, even heating capabilities, making it perfect for small-scale projects. Its 2000W four-sided surround technology guarantees quick temperature rises and uniform heat distribution, preventing hot spots. The digital control offers precise adjustments from 0-1150°C (2102°F) with real-time monitoring, ensuring consistent results whether you’re casting, firing, or burnout. The spacious interior, measuring 16x16x13.8cm, allows you to work on multiple small molds simultaneously. Built with durable, high-temperature materials, this kiln is a reliable, versatile tool for hobbyists and professionals alike, ideal for various ceramic and jewelry applications.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital control with real-time monitoring

- Material/Construction:High-temp resistant materials, reinforced lining

- Additional Feature:2000W four-sided heating

- Additional Feature:Includes multiple accessories

- Additional Feature:Supports diverse firing needs

195x170mm Microwave Kiln for Firing Ceramics and Fused Glass Up to 1200 ℃

The x170mm microwave kiln stands out as an ideal choice for hobbyists and small studio artists who need a reliable, space-saving solution for firing ceramics and fused glass. Its compact design, with external dimensions of 195 x 170mm, makes it easy to store and transport. Capable of reaching up to 1200°C, it heats quickly—melting glass in 6-8 minutes and sintering ceramics in about 15 minutes. Constructed from durable ceramic fiber, it offers excellent heat insulation. Its simple operation makes it accessible for beginners, making it perfect for small projects and home use. This kiln combines efficiency, ease, and space efficiency in one compact package.

- Max Temperature:1200°C

- Power Rating:Not specified

- Chamber Dimensions:φ130 x H90 mm

- Heating Technology:Ceramic fiber heating

- Control System:Digital, easy-to-use interface

- Material/Construction:Ceramic fiber, durable construction

- Additional Feature:Heats in 6-8 minutes

- Additional Feature:Ceramic fiber construction

- Additional Feature:Simple operation design

Electric Burnout Oven Kiln for Ceramic & Jewelry Making

Electrically operated burnout oven kilns excel in precision heating, making them ideal for jewelry makers and small-scale ceramic artists. With a 2000W high-performance heating tube and advanced four-sided surround technology, they deliver even, rapid heating essential for accurate casting and mold work. The intelligent temperature control system allows precise regulation from 0 to 1150℃, ensuring safety and consistency. Its large internal capacity fits multiple molds simultaneously, while ventilation holes prevent overheating. Made from durable, high-temperature materials, these kilns are built to last. Whether for jewelry, dental labs, or glass fusing, they provide a stable environment for professional and DIY projects requiring reliable high-temperature performance.

- Max Temperature:1150°C

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital display, temperature control

- Material/Construction:High-temp resistant materials, reinforced lining

- Additional Feature:16×16×13.8 cm chamber

- Additional Feature:Ventilation holes included

- Additional Feature:Sealed heat loss design

Pro Tabletop Kiln for Pottery & Jewelry Making

Designed for small-scale pottery and jewelry projects, the PRO Tabletop Kiln offers precise temperature control and uniform heating, making it an ideal choice for both hobbyists and professional artisans. With a maximum temperature of 1150°C and a digital display, it ensures accurate, consistent results every time. The four-sided surround heating provides even heat distribution, while rapid heating reduces cycle times and energy costs. Its compact design fits comfortably on a workbench, and the spacious interior (16×16×13.8 cm) allows multiple molds per cycle. Built with durable, high-temperature materials and equipped with real-time sensors, it guarantees safe, reliable operation for all your small-scale ceramic and jewelry projects.

- Max Temperature:1150°C

- Power Rating:Not specified

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital, high-precision sensors

- Material/Construction:High-temp resistant, durable construction

- Additional Feature:Reinforced lining for durability

- Additional Feature:Batch processing capacity

- Additional Feature:Digital temperature monitoring

195x170mm Microwave Kiln for Firing Ceramics and Fused Glass Up to 1200 ℃

If you’re working on small-scale ceramics or fused glass projects, this 120x130mm microwave kiln offers an excellent combination of power and convenience. It’s perfect for firing glass jewelry, ceramics, and other tiny creations up to 1200°C. Its compact size (φ75 x H90mm internal) makes it easy to store and use at home or in a small studio. The kiln heats quickly, melting glass in just 6-8 minutes and sintering ceramics in around 15 minutes. Made from durable ceramic fiber, it’s safe and reliable for high-temperature work. Its simple operation makes it ideal for artists seeking efficient, space-saving firing solutions.

- Max Temperature:1200°C

- Power Rating:Not specified

- Chamber Dimensions:φ75 x H90 mm

- Heating Technology:Four-sided surround heating

- Control System:Digital display, precise regulation

- Material/Construction:Ceramic fiber, sturdy shell

- Additional Feature:Heats quickly for small projects

- Additional Feature:Compact internal size

- Additional Feature:Suitable for glass fusion

VEVOR 1500W Electric Kiln for Metal & Clay

The VEVOR 1500W Electric Kiln stands out as an excellent choice for hobbyists and professionals alike who need precise temperature control and high performance in a compact form. It’s perfect for jewelry making, metal clay, ceramic firing, and metal tempering. With a powerful 1500W heating element, it can reach up to 2192℉/1200℃ in just 34-38 minutes, thanks to even heat distribution. The PID digital control offers accurate temperature adjustments via a clear LED display. Its cooling system guarantees safety and longevity, making it a versatile tool for small workshops or home projects. Overall, it’s a reliable, high-quality kiln for various metal and ceramic applications.

- Max Temperature:1200°C

- Power Rating:1500W

- Chamber Dimensions:Larger chamber, specifics vary

- Heating Technology:PID controlled with surround heating

- Control System:PID control system

- Material/Construction:Metal exterior, high-temp chamber

- Additional Feature:Supports metal melting below 1200°C

- Additional Feature:Cooling holes for wax discharge

- Additional Feature:Large internal chamber

Weysat Kiln Shelf for Glass Fusing and Ceramics

For artists and hobbyists working on small ceramic or glass projects, the Weysat kiln shelf stands out due to its exceptional heat resistance and durability. Made from cordierite and mullite, it withstands temperatures up to 2280°F, ensuring reliable performance during high-temperature firing. Its flat, smooth surface stays scratch- and dent-free, maintaining a flawless finish. Designed to resist warping and thermal shock, it remains stable through multiple cycles. Compact at 7 x 7 inches, it’s perfect for glass fusing and ceramics. Its efficient heat conduction shortens firing times, saving energy and time, making it an essential, versatile tool for any small-scale studio.

- Max Temperature:2280°F (~1249°C)

- Power Rating:2000W

- Chamber Dimensions:16×16×13.8 cm

- Heating Technology:Four-sided surround heating

- Control System:Digital control with temperature sensor

- Material/Construction:High-temp resistant, reinforced lining

- Additional Feature:Made from cordierite/mullite

- Additional Feature:Resists thermal shock

- Additional Feature:Easy to clean surface

Verdanzia 2 Pack 7″ Square Kiln Shelves

Choosing the right kiln shelves can make a significant difference in achieving consistent results with your small ceramics projects. The Verdanzia 2 Pack 7″ Square Kiln Shelves are crafted from a durable blend of cordierite and mullite, offering excellent thermal shock resistance and longevity. Measuring 7.09 inches square with a 0.63-inch thickness, they fit most small to medium kilns and resist warping under heavy loads. These shelves withstand temperatures up to 2280°F, making them versatile for high-fire ceramics, glass fusing, and metal clay. Their smooth surface promotes even heat distribution, ensuring consistent glazes and easy cleanup, making them a reliable choice for any small-scale firing.

- Max Temperature:2280°F (~1249°C)

- Power Rating:Not specified (but likely 2000W based on similar models)

- Chamber Dimensions:7×7 inches (≈18×18 cm)

- Heating Technology:Programmable with high-temp elements

- Control System:Programmable controller with digital interface

- Material/Construction:Metal shell, high-temp materials

- Additional Feature:High thermal resistance

- Additional Feature:Even heat distribution

- Additional Feature:Suitable for high-fire projects

Factors to Consider When Choosing a Tabletop Kiln for Small Ceramics

When selecting a tabletop kiln for small ceramics, I look at several key factors to ensure it meets my needs. Considering the temperature range, size, heating uniformity, safety features, and material durability helps me make an informed choice. These points are vital for achieving consistent results and safe operation.

Temperature Range Needs

Ensuring your tabletop kiln can reach and maintain the necessary temperatures is vital for successful small ceramic firing. Most small ceramics require a firing temperature around 1000°C to 1150°C, so your kiln should have a temperature range that exceeds this maximum to accommodate different materials and firing schedules. Precise temperature control is equally important to prevent under- or over-firing delicate pieces, which could compromise their structure and appearance. Look for kilns with reliable sensors and digital controls that maintain consistent heat throughout the firing process. Additionally, verify that the maximum temperature capacity aligns with your specific ceramic materials. Gradual heating and cooling features are also indispensable to avoid thermal shock and cracking, ensuring your finished pieces are strong and beautifully fired.

Size and Capacity

The size and capacity of a tabletop kiln directly influence how many small ceramics you can fire at once and how well it fits into your workspace. Internal chamber dimensions, like 16×16×13.8 cm or 15x15x20 cm, determine the volume available for your pieces. A larger capacity allows you to process multiple items simultaneously, boosting efficiency for batch firing. Conversely, compact kilns with chambers around 12x13x9 cm are ideal for tiny projects or individual pieces, saving space without sacrificing performance. Keep in mind that larger chambers often need more powerful heating elements to reach high temperatures evenly. Additionally, the overall size impacts where you can place the kiln and its portability, which is vital for small studios or home setups.

Heating Uniformity

Achieving consistent results in small ceramic firing depends heavily on how evenly the heat is distributed inside the kiln. I look for kilns with four-sided surround heating technology, which guarantees that heat reaches every interior surface uniformly. Precise temperature regulation systems like PID controllers help maintain stable temperatures, reducing hot spots and uneven firing. High-quality heating elements and thickened wiring contribute to consistent heat distribution, minimizing temperature gradients. Proper insulation and sealed door designs are also essential, as they prevent heat loss and promote even temperatures throughout the firing process. Additionally, regular calibration and maintenance of sensors and heating components are critical to sustain uniform heat distribution over time. These features collectively ensure reliable, even firing results for small ceramics.

Safety Features Included

When choosing a tabletop kiln for small ceramics, safety features should be a top priority. Sealed doors and insulation help prevent heat loss and protect against burns during operation. High-temperature-resistant materials and reinforced linings ensure the kiln stays structurally sound under intense heat, reducing the risk of accidents. Digital temperature controls with real-time monitoring enable precise adjustments, lowering the chance of overheating or fires. Cool-to-touch exterior surfaces improve safety during handling, while safety switches provide an extra layer of protection. Overheat protection systems and automatic shut-off mechanisms are essential for preventing mishaps and ensuring safe operation. By prioritizing these safety features, you can craft confidently, knowing your kiln is designed to keep you safe while working with small ceramics.

Material Durability

Choosing a tabletop kiln that’s built to last depends heavily on its materials’ ability to withstand repeated high-temperature firing without cracking or degrading. I look for kilns with chambers lined with refractory bricks or high-temperature ceramics, as these resist thermal shock and maintain integrity over time. The kiln shelf and interior components, such as those made from cordierite or mullite, should endure frequent heating without warping or cracking. Durable construction also involves reinforced wiring and thick linings that handle heat expansion and contraction effectively. High-quality materials ensure consistent performance and safety, which means fewer repairs and replacements in the long run. Ultimately, investing in a kiln with resilient materials guarantees reliable operation and longevity for my small ceramic projects.

Control Precision Level

Since small ceramics are highly sensitive to temperature variations, precise control over firing conditions is critical. I look for kilns that can maintain temperature fluctuations within ±1°C, which helps prevent warping or cracking. Digital PID controllers are a game-changer, allowing me to program accurate firing cycles and ensure consistent results. The ability to set specific temperature profiles is essential for processes like glaze and bisque firing, giving me control over each stage. High-precision sensors enable real-time monitoring, so I can detect and correct deviations immediately, maintaining stability. Adjustable ramp rates and soak times are also valuable, as they let me fine-tune my firing schedule. Overall, a kiln with excellent control precision guarantees my small ceramics are fired evenly and reliably.

Price and Budget

Setting a realistic budget is essential to narrowing down your options and avoiding overspending on features you don’t need. Prices for tabletop kilns range from around $200 to over $1500, depending on size, temperature capacity, and control features. Higher-priced models typically include advanced digital controls, better insulation, and safety features that enhance usability and durability. However, budget-friendly options may lack precise temperature regulation or safety safeguards, which can impact firing quality and safety. It’s important to take into account the total cost, including shipping and accessories, to guarantee the kiln fits within your financial plan. Comparing these costs helps you avoid hidden expenses and select a kiln that balances performance with affordability, making sure you get good value for your investment.

Frequently Asked Questions

What Safety Features Are Essential in a Tabletop Kiln?

Safety features like a sturdy lid lock, automatic shut-off, and thermal insulation are essential in a tabletop kiln. I always look for a kiln with a reliable temperature controller to prevent overheating. A built-in kiln sitter or thermal fuse provides extra protection, and an easy-to-read display helps me monitor the process closely. These features give me peace of mind while working, ensuring safety for both me and my ceramics.

How Energy-Efficient Are These Small Ceramic Kilns?

Think of a small ceramic kiln as a tiny power plant—efficiently transforming energy into finished art. Most tabletop kilns today are quite energy-conscious, often boasting features like insulated walls and programmable settings that minimize power waste. While they do consume electricity, many models are designed to optimize heating cycles, saving energy and reducing costs. So, with careful use, these kilns can be quite eco-friendly and budget-smart for your small projects.

Can These Kilns Be Used for Glass Fusing?

Yes, many small tabletop kilns can be used for glass fusing, but it depends on their temperature range and features. I recommend checking if the kiln reaches the necessary 1400°F to 1500°F for fusing glass. I’ve found that models with a digital controller and even heat distribution work best. Always verify the kiln is rated for glass work to avoid damage or safety issues.

What Is the Typical Lifespan of a Tabletop Kiln?

A tabletop kiln’s lifespan is like a well-tended garden—lasting many seasons with proper care. On average, it’s around 8 to 10 years, but with regular maintenance and gentle handling, some can thrive for 15 years or more. I’ve seen dedicated artists enjoy decades of creativity from their kilns, turning small sparks into lasting masterpieces. Proper usage and upkeep truly help your kiln stand the test of time.

Are Replacement Parts Readily Available for These Kilns?

Yes, replacement parts for tabletop kilns are generally easy to find. I’ve discovered that most manufacturers maintain a stock of essential components like elements, thermocouples, and controllers, making repairs straightforward. When I needed a new element, I contacted the supplier, and they shipped it quickly. It’s always a good idea to choose a reputable brand with readily available parts, so you can keep your kiln running smoothly for years.

Conclusion

No matter which kiln I choose, I know it’s like finding the right brush for a masterpiece—essential for perfect results. With so many great options out there, you’re bound to find one that sparks your creativity. Think of your kiln as the heartbeat of your small ceramic projects—reliable, steady, and always ready to bring your ideas to life. Happy firing, and may your creations flourish!